How to Streamline Quality Control in Manufacturing for Business Central

Why Manufacturers Need a Smarter Quality Control Solution

Manufacturing companies face constant pressure to deliver high-quality products control while maintaining efficiency and compliance. Traditional paper-based or spreadsheet-driven inspection processes create bottlenecks, increase human error, and lack real-time visibility.

Quality Inspector is a fully integrated quality control solution for Microsoft Dynamics 365 Business Central, designed to help manufacturers automate inspections, enforce compliance, and optimize production quality. This article explores how Quality Inspector addresses modern manufacturing challenges and how businesses can leverage it to enhance their quality management processes.

Listen to the podcast: Building Quality In: Real-Time Inspection in Business Central with Quality Inspector

What Is Quality Inspector?

Quality Inspector is a manufacturing quality control software that integrates directly with Microsoft Dynamics 365 Business Central. It enables companies to implement real-time quality inspections, reducing defects, improving compliance, and ensuring consistent product standards.

Key Features:

- Customizable Quality Inspection Templates – Define test parameters for different products and processes.

- Automated Test Generation – Trigger inspections automatically based on receiving, production, or shipping events.

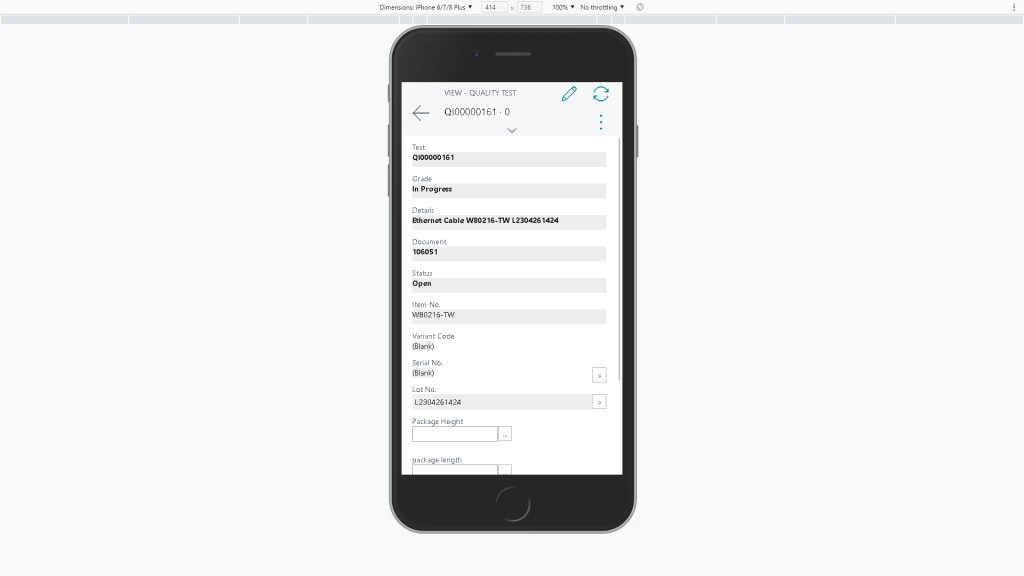

- Mobile-Optimized Data Entry – Perform inspections directly on tablets or mobile devices.

- Blocking & Compliance Enforcement – Restrict inventory transactions for failed inspections.

- Advanced Analytics & Reporting – Export data to Excel, Power BI, or internal dashboards.

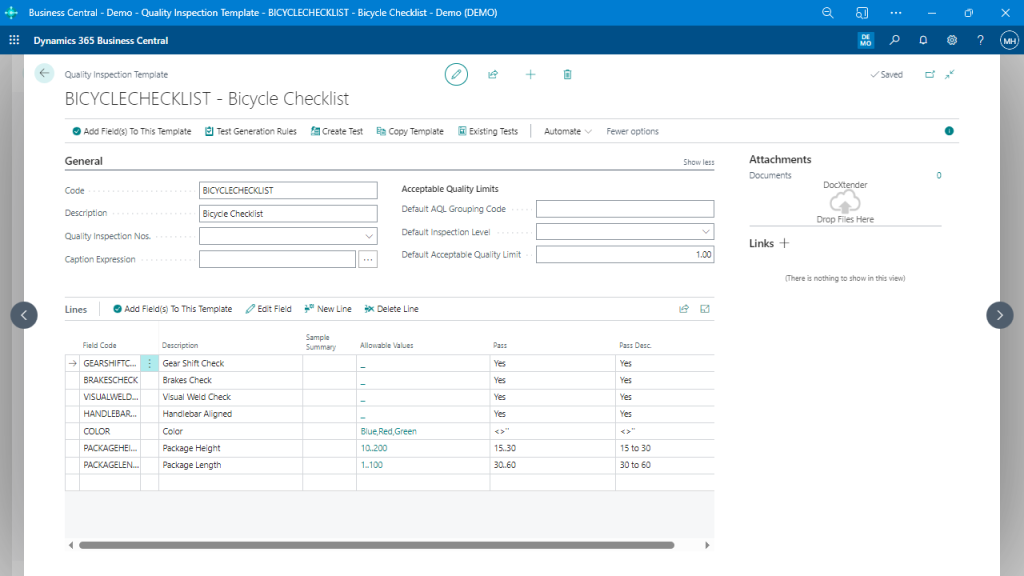

Setting Up a Quality Inspection Template

One of the most powerful features of Quality Inspector is its ability to customize inspection templates based on specific manufacturing needs.

For example, a manufacturer assembling bicycles can set up an inspection template to verify:

- Gear shift alignment

- Brake function

- Visual weld quality

- Frame color and packaging dimensions

Once set up, Quality Inspector can automatically apply this template whenever a new batch is received or before the product moves to the next stage in production.

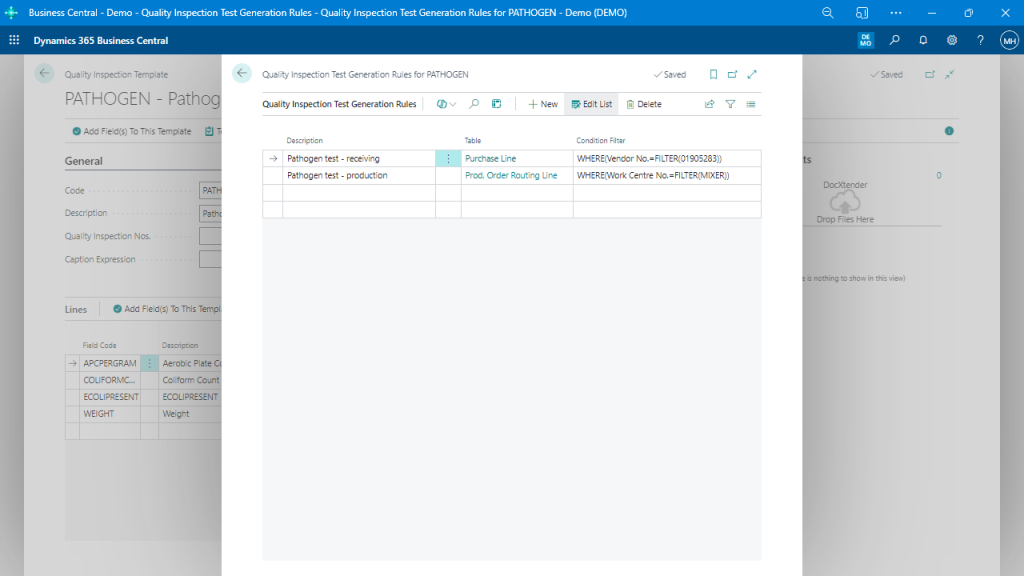

Automating Quality Inspections in Manufacturing

One of the biggest challenges manufacturers face is ensuring quality checks happen at the right time—without slowing down production. Quality Inspector solves this by automating test creation based on:

- Purchase Orders (Receiving Inspections) – Ensure suppliers meet quality standards before materials enter production.

- Production Orders (In-Process Inspections) – Catch defects early before products move to the next step.

- Pre-Shipment Checks (Final Inspections) – Guarantee products meet specifications before they leave the facility.

With automated triggers, businesses can enforce quality at every stage of production—eliminating manual tracking and reducing defects.

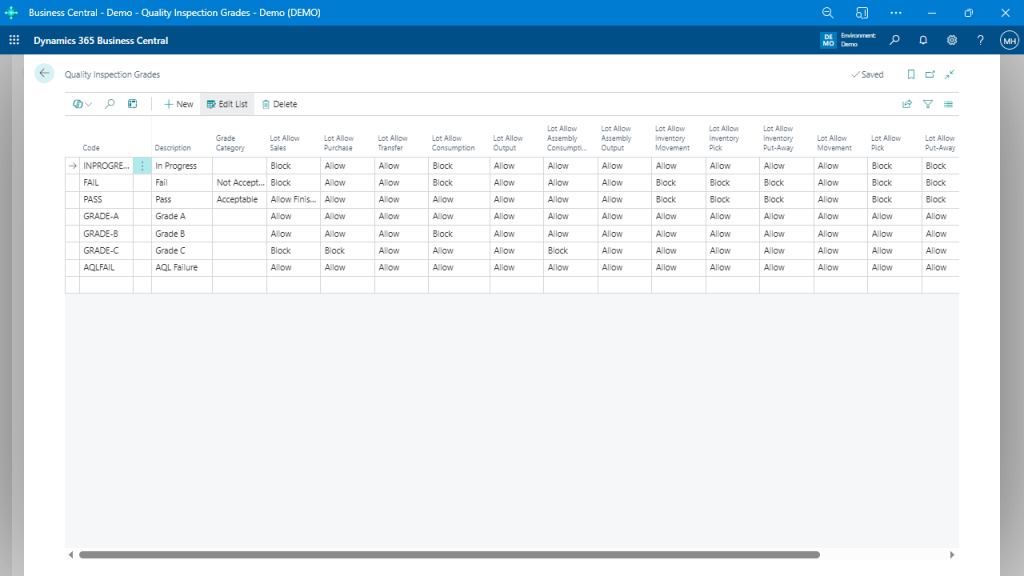

Blocking Non-Compliant Inventory & Enforcing Compliance

Failed inspections aren’t just logged—they trigger real-time inventory restrictions within Business Central.

- If a material batch fails, it can be automatically blocked from production, preventing it from being consumed, shipped, or sold. This ensures compliance with ISO 9001, FDA, and other industry regulations.

Example: A food manufacturer testing a dairy ingredient for bacterial contamination can configure Quality Inspector to block any batch that exceeds regulatory limits before it enters the production line.

Quality Reporting & Data-Driven Decision Making

Tracking and analyzing inspection data is essential for continuous improvement. Quality Inspector integrates with:

- Power BI for real-time dashboards

- Excel for exporting test results

- Microsoft Teams for collaboration

Manufacturers can:

- Identify defect trends over time.

- Compare supplier quality performance.

- Generate Certificates of Analysis for compliance.

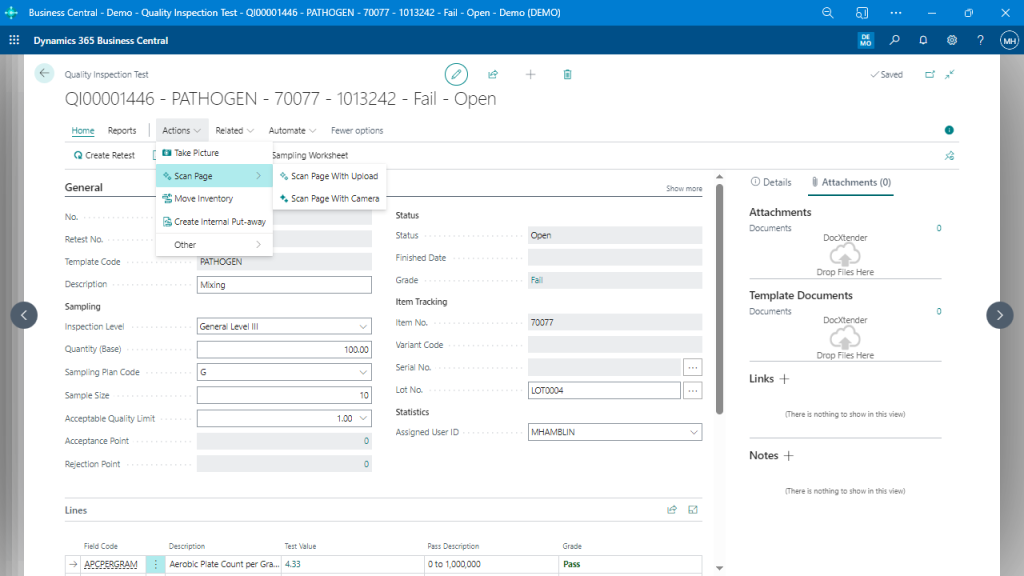

Mobile-Optimized Quality Inspections

Quality checks don’t have to be tied to a desktop. With Quality Inspector’s mobile-friendly interface, inspectors can conduct inspections on the shop floor using tablets or mobile devices.

Features include:

- Touchscreen data entry

- Photo capture for defect tracking

- Barcode scanning for lot traceability

Conclusion: Why Manufacturers Need to Upgrade to Digital Quality Control

In today’s competitive landscape, manual inspections and outdated spreadsheets are no longer sustainable. Quality Inspector helps manufacturers:

- Reduce defects & rework costs

- Enforce compliance with industry regulations

- Improve efficiency with automated quality checks

- Gain real-time visibility into quality trends