Why Shift Scheduling Matters: How to Optimize Labor Costs in Business Central

FREE Membership Required to View Full Content:

Joining MSDynamicsWorld.com gives you free, unlimited access to news, analysis, white papers, case studies, product brochures, and more. You can also receive periodic email newsletters with the latest relevant articles and content updates.

Learn more about us here

In manufacturing, balancing labor costs with production demands is critical. Overstaffing increases costs unnecessarily, while understaffing leads to missed deadlines and decreased efficiency. That’s where Shop Floor Insight, a Manufacturing Execution System (MES) for Microsoft Dynamics 365 Business Central, comes in.

With automated shift scheduling, real-time tracking, and employee time management, Shop Floor Insight ensures that the right people are on the floor at the right time—without inflating payroll expenses.

Listen to the podcast: Smarter Shift Scheduling: Reducing Labor Costs and Boosting Efficiency in Business Central

The Cost of Inefficient Scheduling

Manufacturers often struggle with:

- Labor cost overruns due to unnecessary overtime.

- Production delays when shifts aren’t aligned with demand.

- Administrative overhead from manual scheduling and approvals.

- Employee dissatisfaction when schedules lack flexibility.

These challenges make data-driven scheduling a necessity. Shop Floor Insight offers a structured approach to shift management, ensuring optimal workforce allocation and cost control.

Smart Shift Scheduling with Shop Floor Insight

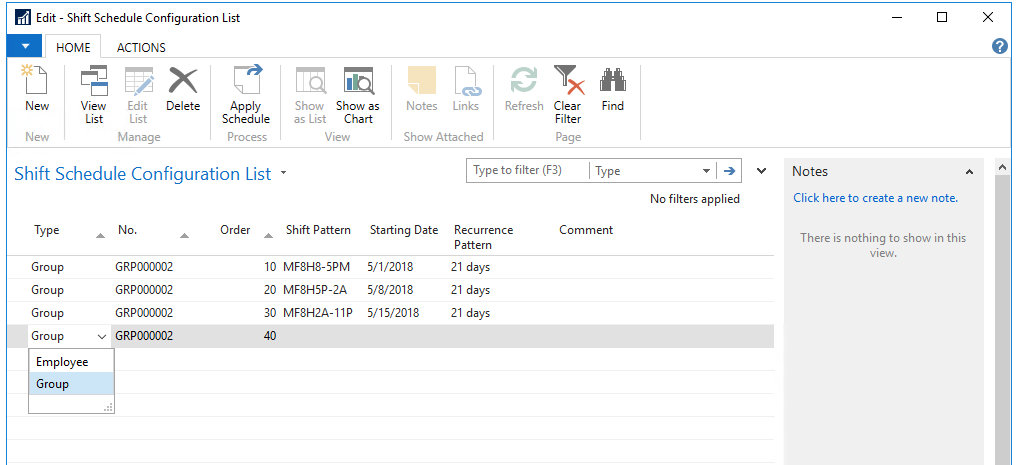

1. Automated Recurring Shift Patterns

Instead of manually assigning shifts every week, Shop Floor Insight allows manufacturers to define recurring shift patterns. This feature simplifies workforce management while ensuring that shift allocation matches production requirements.

Example: A manufacturer with three rotating shifts can apply a predefined shift pattern that cycles employees through morning, afternoon, and night shifts automatically.

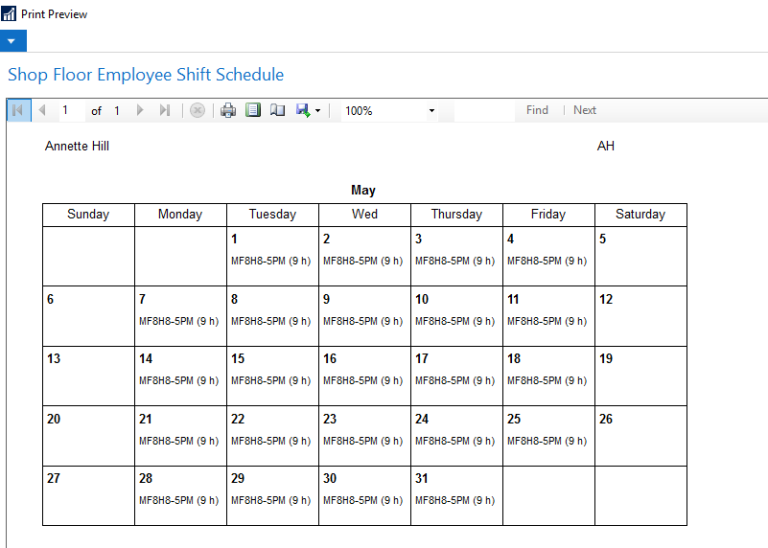

2. Visual Shift Calendar for Easy Adjustments

Shop Floor Insight includes a visual scheduling calendar, making it easy for managers to see current and upcoming shifts at a glance. Adjustments can be made in seconds, ensuring that labor resources remain optimized.

This is especially useful in dynamic manufacturing environments where demand fluctuates, and schedules must be updated on the fly.

Example: A last-minute order requires extra workers on the night shift. With a few clicks, a supervisor can adjust the schedule and notify employees automatically.

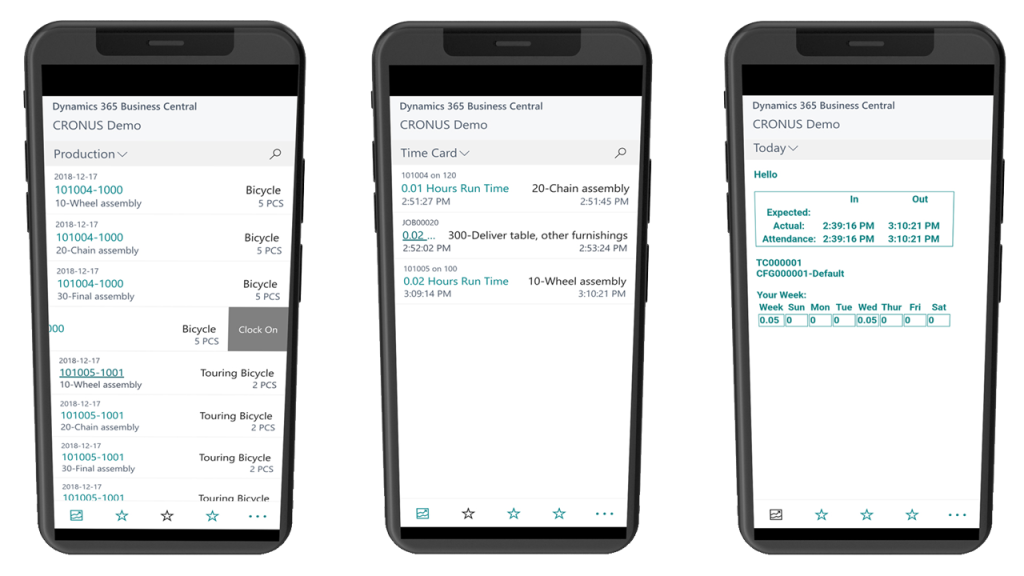

3. Accurate Time Tracking, Mobile Accessibility & Payroll Integration

Tracking employee time manually is not only time-consuming but also prone to errors. Shop Floor Insight simplifies this process with barcode-based time tracking and mobile accessibility, allowing employees to clock in and out seamlessly—whether on the shop floor or remotely.

- ✔ Employees can scan a barcode or tap their mobile device to clock in/out, reducing errors and eliminating paper timecards.

- ✔ Supervisors can monitor real-time attendance from anywhere, ensuring labor is aligned with production schedules.

- ✔ Mobile access enables employees to check their shifts, request changes, and view worked hours directly from their devices.

- ✔ Automated approvals streamline payroll processing, eliminating double data entry and compliance issues.

- ✔ Overtime tracking helps avoid unnecessary labor costs and ensures accurate compensation.

Example: A factory using traditional punch clocks struggled with inaccurate time records and excessive administrative work. By switching to Shop Floor Insight’s mobile time tracking, employees can now log their hours in real-time using a mobile app, while managers receive immediate insights into labor costs and shift coverage.

4. Real-Time Insights into Labor Utilization

Shop Floor Insight provides real-time labor data, allowing managers to analyze trends, identify inefficiencies, and make informed scheduling decisions. This ensures that shifts align with production demands and that staffing levels are neither too high nor too low.

Example: A factory notices a consistent drop in productivity on Monday mornings. After analyzing shift data, they discover excessive overtime on Sunday, leading to worker fatigue. Adjusting shift schedules improves efficiency.

The Bottom Line: Reduce Costs, Improve Productivity

Manufacturers using Shop Floor Insight for shift scheduling can expect:

- ✔ Lower labor costs by reducing unnecessary overtime.

- ✔ Increased efficiency with better workload distribution.

- ✔ Improved employee satisfaction through predictable, well-structured schedules.

- ✔ Streamlined payroll processing with accurate time tracking.

By leveraging Shop Floor Insight’s scheduling and time tracking features, manufacturers can balance workloads, control costs, and improve overall shop floor efficiency.