When Quality Controls Break Down in Business Central

Failed Material Moving Through Operations

Quality management processes relying on paper checklists and disconnected workflows often result in failed or nonconforming materials making their way through receiving, production, and shipping. Operators and inspectors may see missed or delayed inspections, incomplete documentation, or inconsistent enforcement of pass/fail criteria.

In practice, this means defective items can be shipped to customers or used in production before any corrective action occurs. Auditors find it difficult to trace inspection histories or follow up on corrective actions, leading to audit risks and compliance challenges.

Listen to the Podcast

Quality Processes Lacking Integration

The lack of integrated quality management within operational workflows causes inspection results and corrective actions to be disconnected from the actual movement of goods. Paper-based checks introduce delays and documentation gaps, and non-automated pass/fail controls rely on manual follow-up.

Since inspection outcomes are not tied to inventory statuses or production steps within the system, nonconforming materials can proceed unchecked. This structural gap makes it natural for failures to slip through and corrective action to be applied inconsistently or too late.

Quality Controls Embedded in Operations

To prevent quality failures, inspection and testing outcomes must be automatically linked to inventory and production workflows. This requires enforcement of pass/fail rules that can trigger quarantines and nonconformance handling directly within operational processes.

Real-time capture of inspection data, automated triggering of corrective actions, and traceability throughout goods receipt, production, and finished goods storage are essential capabilities. These controls ensure defective materials are prevented from advancing in the supply chain without manual follow-up delays.

How Business Central Supports Quality Management Workflows

Microsoft Dynamics 365 Business Central includes quality inspection records and batch attributes, allowing users to document inspections tied to receipts or production. The system can record pass/fail outcomes and track quarantined inventory manually.

However, native Business Central does not enforce inspection results automatically within warehouse or production workflows. Nonconformance management and corrective actions are typically handled outside of core inventory processes, relying heavily on manual coordination and external documentation.

When Standard Controls Aren't Enough

Standard Business Central functionality falls short when inspection enforcement must be automatic and linked closely to operational execution. Without integrated barcode-driven data capture and real-time pass/fail validation, nonconforming items can bypass controls, causing production delays, rework, or shipment of defective goods.

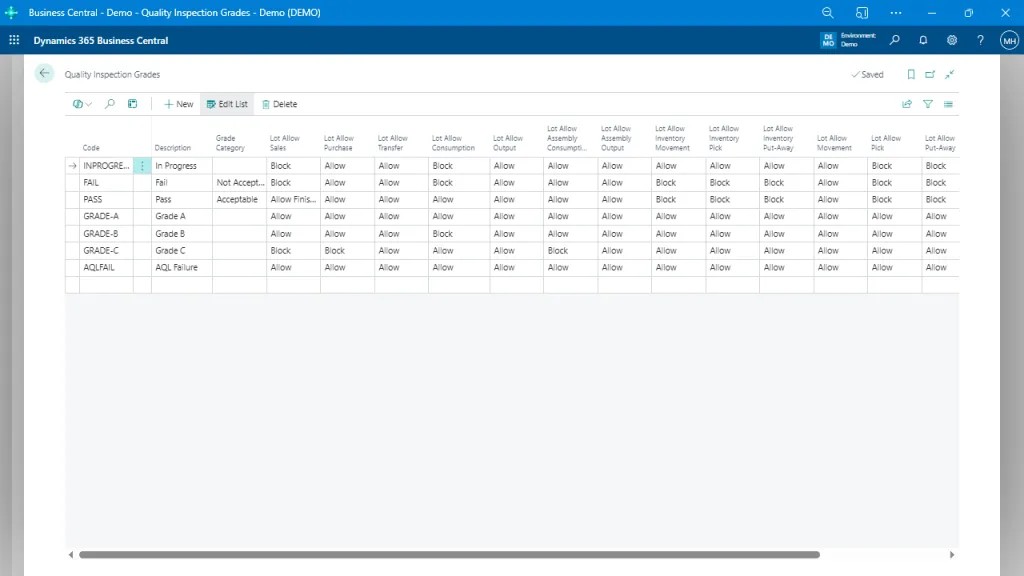

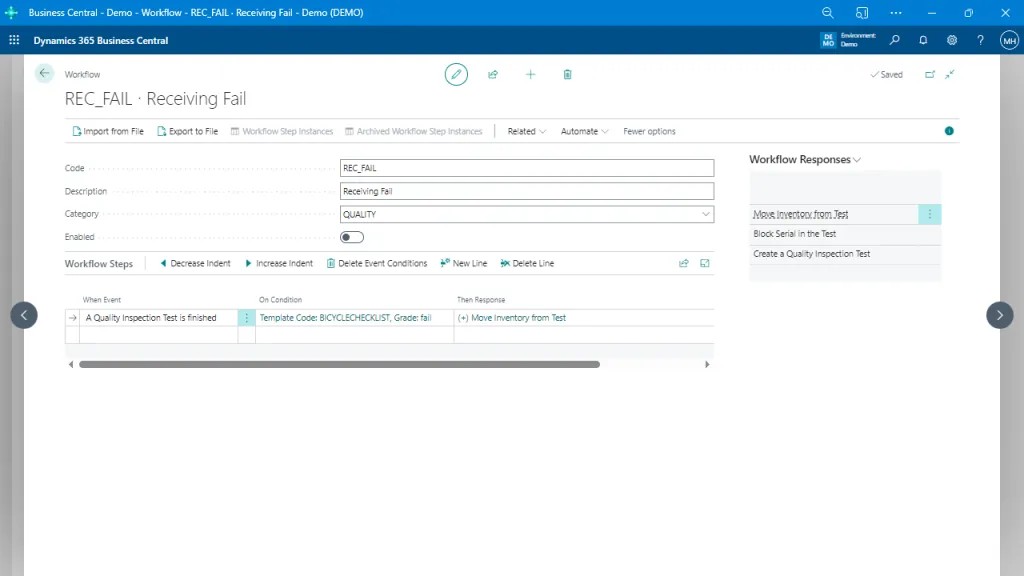

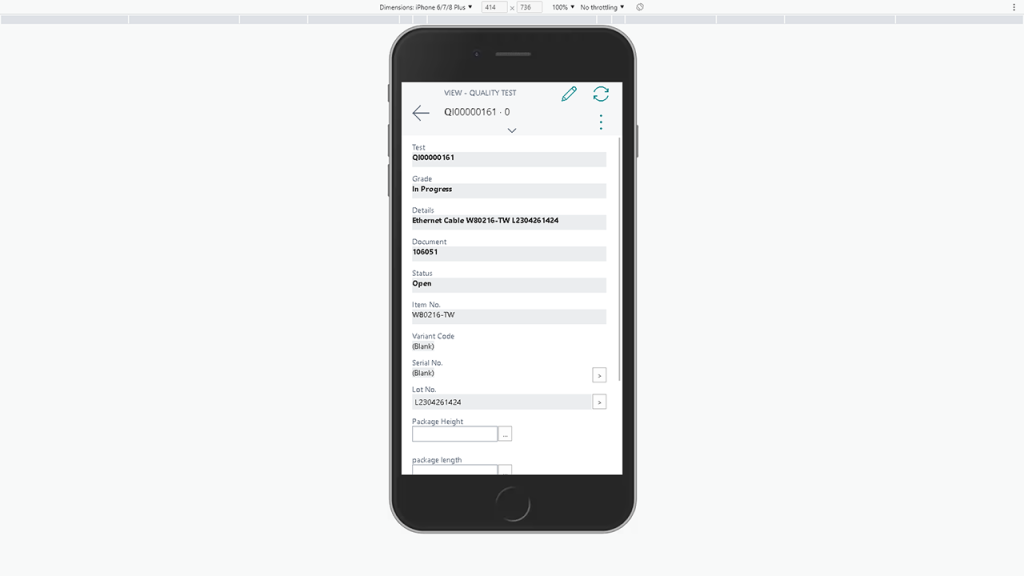

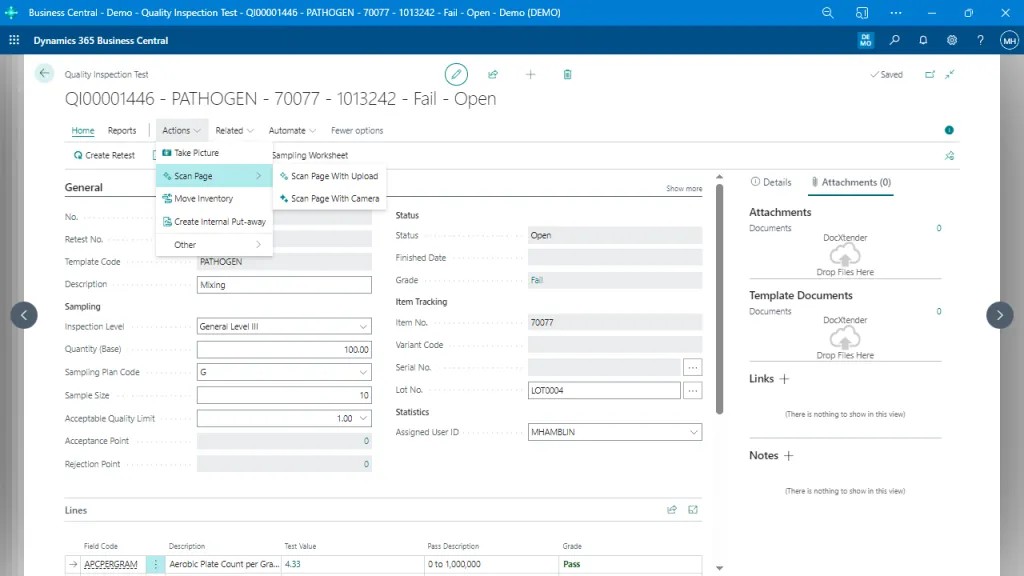

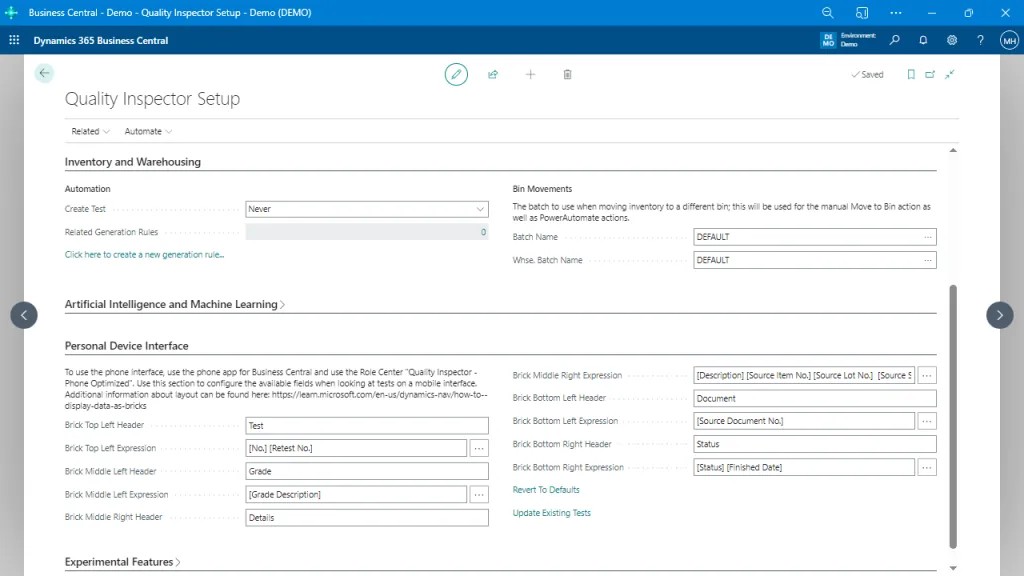

Insight Works offers the Quality Inspector app, which embeds quality inspections directly into Business Central workflows. It automates inspection creation at receipt, during production, and for finished goods, enforcing pass/fail rules and quarantines systematically. This ensures that defective material cannot progress until corrective actions and retesting are complete.

Complementary Insight Works apps like Warehouse Insight and Shop Floor Insight support accurate inventory handling and in-process data capture, enabling seamless quality control as part of standard warehouse and production mobile workflows. These operational extensions provide the necessary control, traceability, and audit readiness that standard Business Central alone does not deliver.

Quality Management Requires Embedded Controls

Quality issues that stem from disconnected inspections and manual paperwork are a structural challenge in many operations. Effective control depends on embedding quality checks and enforcement directly into warehouse and production workflows to ensure consistent adherence and traceability.