The Best Way to Handle Corrective vs. Preventive Maintenance in Business Central

In manufacturing, maintenance generally falls into two categories: planned maintenance and unplanned repairs. On one side, you have preventive maintenance—routine checks and servicing that help avoid issues before they start.

On the other side, corrective maintenance steps in after something breaks. Most teams struggle to balance both, especially when they’re stuck using disconnected tools or manual processes.

The Maintenance Manager app from Insight Works streamlines maintenance, maximizes uptime, and ensures assets last longer. With Maintenance Manager, businesses using Microsoft Dynamics 365 Business Central manage both corrective and preventive maintenance within a single, integrated workflow.

Let’s break down how to set up each type—and more importantly, how to make them work together.

Understand the Difference: Corrective vs. Preventive

To begin, you should clarify what separates these two maintenance types.

| Maintenance Type | Purpose | Timing | Trigger |

|---|---|---|---|

| Preventive | Prevent failures | Scheduled | Based on time, runtime, or output |

| Corrective | Fix issues | As needed | After breakdowns or user reports |

Both play critical roles in extending asset life and keeping operations running. Preventive maintenance reduces long-term risk. Corrective maintenance addresses short-term emergencies.

When both live in the same system, your team responds faster and plans smarter.

Step 1: Build a Preventive Maintenance Plan

Start with the equipment you want to maintain. In Business Central, you’ll define assets using Maintenance Equipment Items. Then, you’ll attach Preventive Maintenance Tasks that automatically trigger work orders at specific intervals.

To do this:

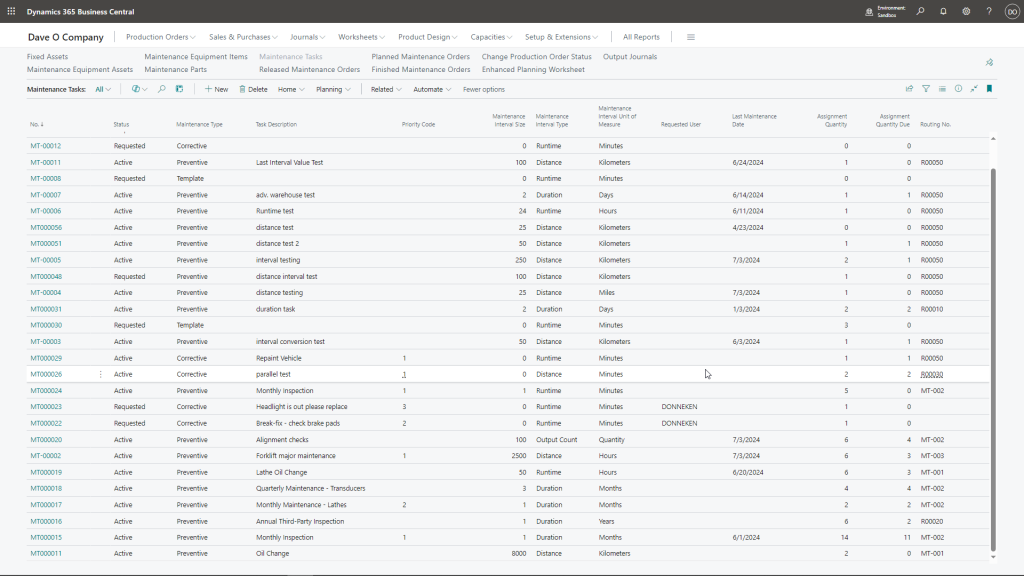

- Go to Maintenance Tasks

- Create a new task and set the Maintenance Type to “Preventive”

- Link it to one or more equipment items

- Choose the maintenance intervals:

- Time-based (e.g., every 30 days)

- Runtime-based (e.g., every 500 hours)

- Output-based (e.g., every 10,000 units)

The interface illustrates how Tasks are created, including interval settings, equipment assignments, and task-specific details such as Bills of Materials (BOMs) and Routings.

Once you assign intervals, move to the Auto Schedule Tasks function. This tool checks all intervals and creates planned maintenance orders for anything due within your selected time window.

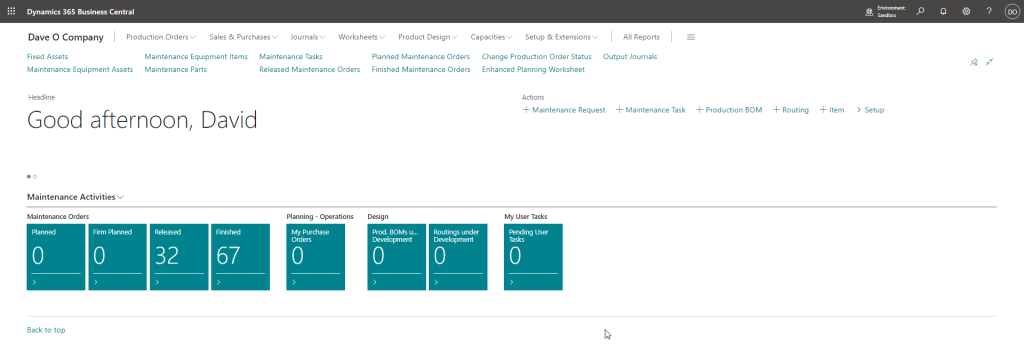

The Maintenance Manager Administration Role Center is featured, providing all necessary links for setting up and managing the maintenance processes within Microsoft Dynamics 365 Business Central.

Preventive tasks now run on autopilot, reducing the chance of missed service windows or unexpected downtime.

Step 2: Capture Corrective Maintenance Instantly

Preventive work reduces surprises, but unplanned breakdowns still happen. When they do, your team needs a fast way to capture and respond to them—without breaking your workflow.

Maintenance Manager provides a simple Maintenance Request feature. Any user in Business Central can use it to report an issue in real time.

Here’s how:

- Open the Maintenance Request page

- Choose the equipment with the issue

- Add a short description (e.g., “Hydraulic leak on press #4”)

- Set a priority level

- Submit the request

This process instantly creates a Corrective Maintenance Task, which you manage just like a scheduled task. You assign resources, track parts, and execute the work order—no manual re-entry needed.

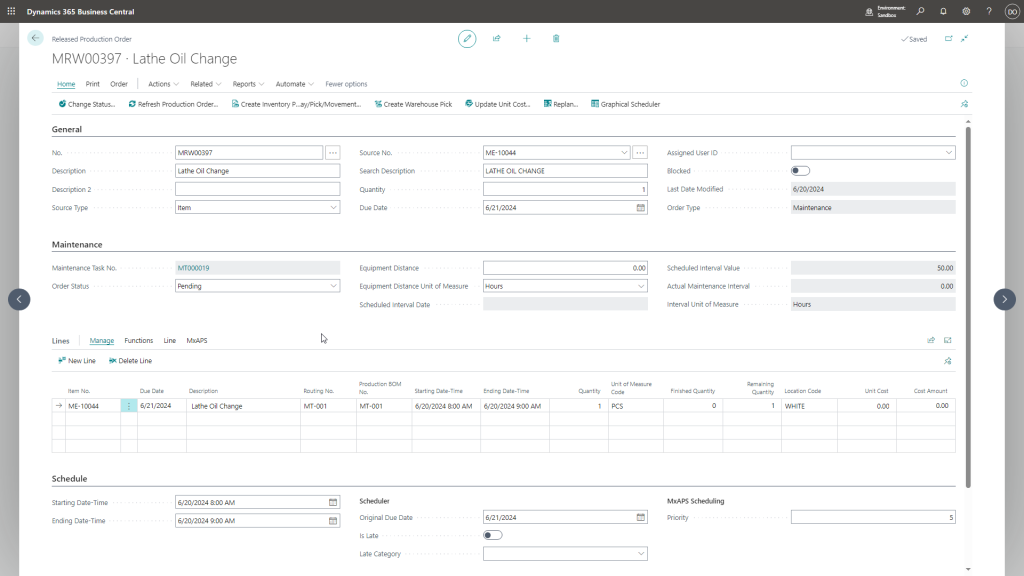

This interface in the Insight Works Maintenance Manager app manages maintenance orders, providing tools for updating order statuses, managing inventory movements, and integrating advanced scheduling features like MxAPS and Graphical Scheduler.

This way, corrective maintenance fits into your existing scheduling, planning, and reporting systems without disruption.

Step 3: Manage Everything from One Central Hub

Instead of juggling two different processes, the Maintenance Manager pulls both preventive and corrective work into a unified dashboard.

From the Maintenance Tasks and Orders lists, your team can:

- View all open and scheduled maintenance tasks

- Filter by task type, status, or equipment

- Track active, completed, and overdue jobs

- Schedule resources and parts more effectively

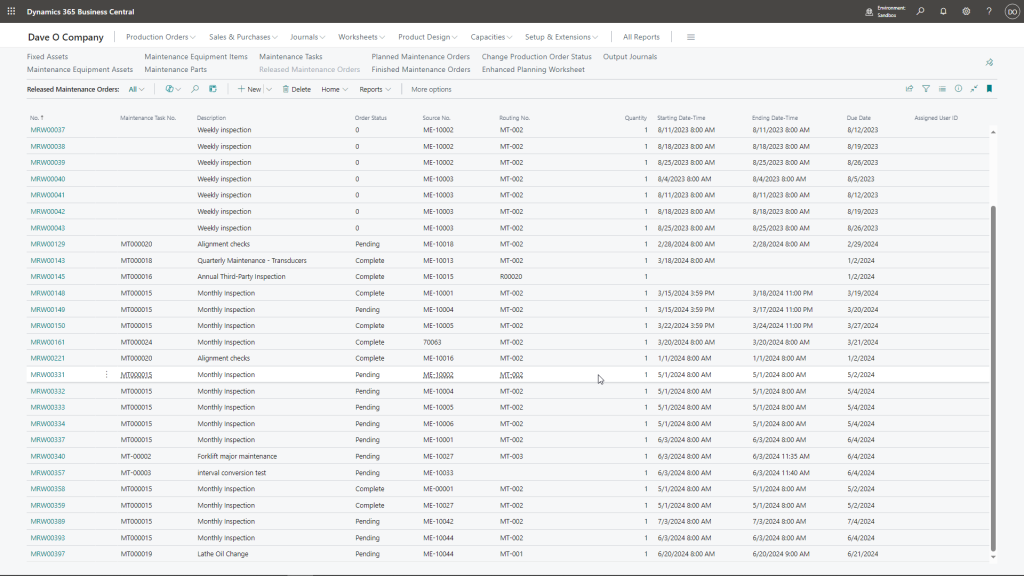

Displayed is the Maintenance Released Order listing, which includes the active maintenance orders generated from the tasks.

With both maintenance types in one place, you gain complete visibility into your asset care process. Nothing falls through the cracks.

Step 4: Stay Ahead with Data and Insights

Over time, the system collects detailed maintenance history for each asset. You can:

- Analyze how often corrective tasks occur

- Adjust preventive intervals based on actual wear and tear

- Spot problem equipment that needs replacement or redesign

- Track technician time and part usage for accurate costing

Business Central already tracks production data, inventory, and labor. Maintenance Manager connects the dots—so your maintenance strategy stays aligned with actual shop floor conditions.

Final Thoughts

You don’t need separate tools or complex spreadsheets to manage maintenance. With the Maintenance Manager app for Microsoft Dynamics 365 Business Central, your team handles both scheduled and emergency work in the same place.

Set up automated preventive tasks based on real usage. Capture corrective issues the moment they happen. Manage both with a streamlined workflow that feeds into your inventory, production, and scheduling systems.

Looking for a more innovative, more efficient way to manage maintenance? Visit MaintenanceForDynamics.com or contact your Microsoft Partner to get started with Maintenance Manager today.