How to Improve Product Quality Using Business Central (Let Power BI and Excel Show You)

When product quality drops, it typically doesn’t begin with a significant failure. It starts small.

- A test fails.

- A batch gets flagged.

- A shipment runs late because someone is double-checking specs.

These issues accumulate, and they cost both time and money.

If you’re using the Quality Inspector app from Insight Works in Microsoft Dynamics 365 Business Central, you’re already capturing the information needed to identify and address those problems early.

Quality Inspector streamlines your quality control process to reduce rework and maximize customer satisfaction. The app gives you detailed test data—now it’s time to put that data to work.

With Excel and Power BI, you don’t need to guess what’s going wrong. These tools help you identify patterns, make informed decisions, and address issues before they escalate.

The Problem: Lots of Data, Not Enough Insight

The Quality Inspector app tracks a wide range of details, including test results, field values, pass/fail grades, operators, timestamps, and more. That’s great—but if you only look at one record at a time, it’s hard to see the bigger picture.

You might wonder:

- Why does this item fail so often?

- Are we experiencing more issues with a single supplier?

- Do certain shifts produce lower-quality output?

Without a straightforward way to review and analyze your test data, these answers stay hidden.

The Fix: Use Excel and Power BI to Find Patterns

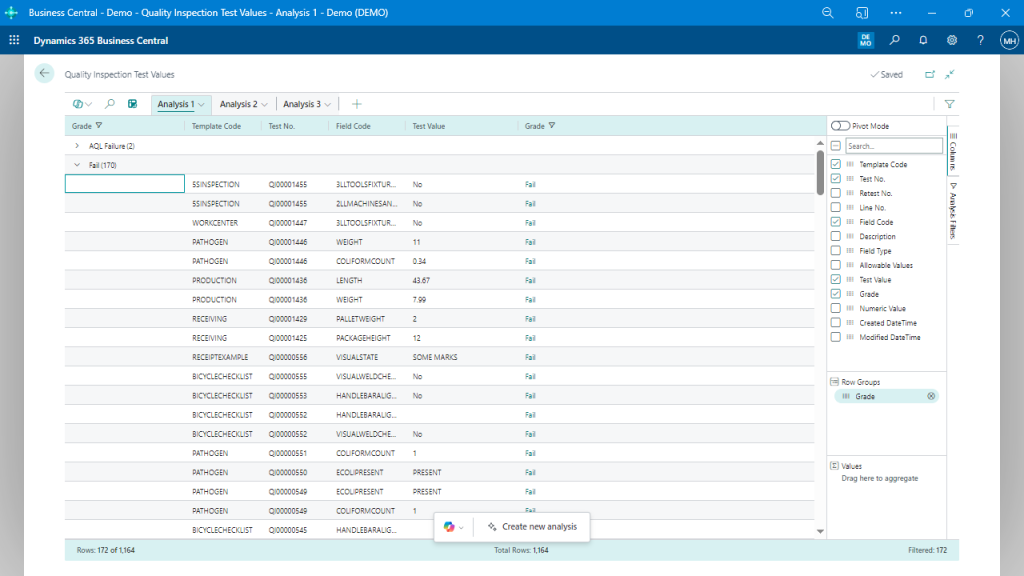

Start by going to the Quality Inspection Test Values page in Business Central. Use filters to focus on the results you care about—like a specific item, test type, or grade.

Analyze detailed test results with a comprehensive overview of quality control outcomes and insights into quality inspection metrics like test numbers, field codes, and pass/fail grades.

Once you’ve filtered your data, export it to Excel.

In Excel, build a pivot table to group results by item number, vendor, or test field. Use conditional formatting to highlight frequent failures. Add charts to track how test results change over time.

If you want something more visual, connect the data to Power BI and use it to build dashboards that display pass/fail rates, highlight trends, and track changes over time.

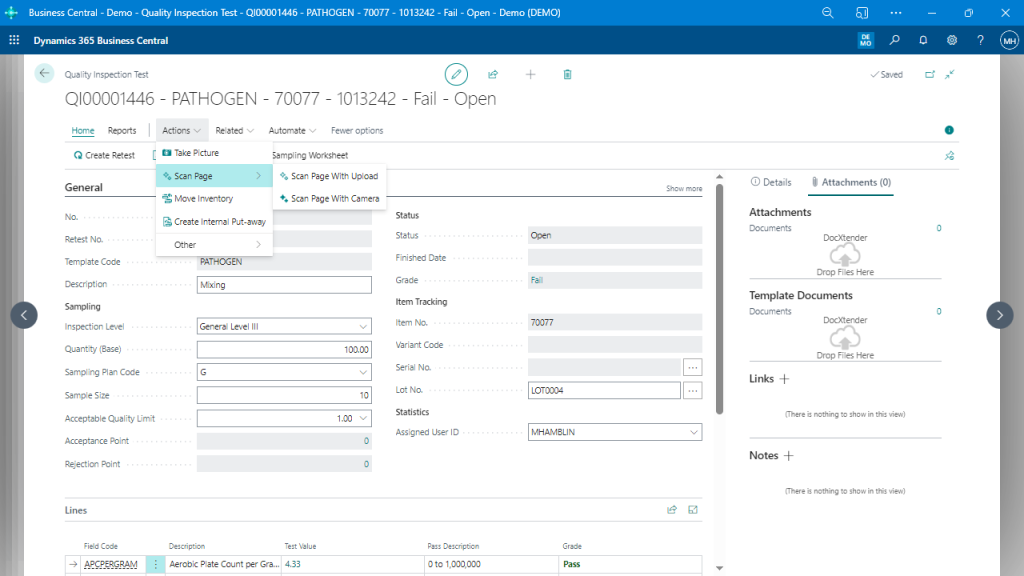

Set quality inspection tests for a specific product batch, including pass/fail status for tested attributes, improving quality assessments.

Once You See the Patterns, Do Something With Them

Spotting trends is only the first step. You need to follow up with changes that improve quality. Here are four ways to do that:

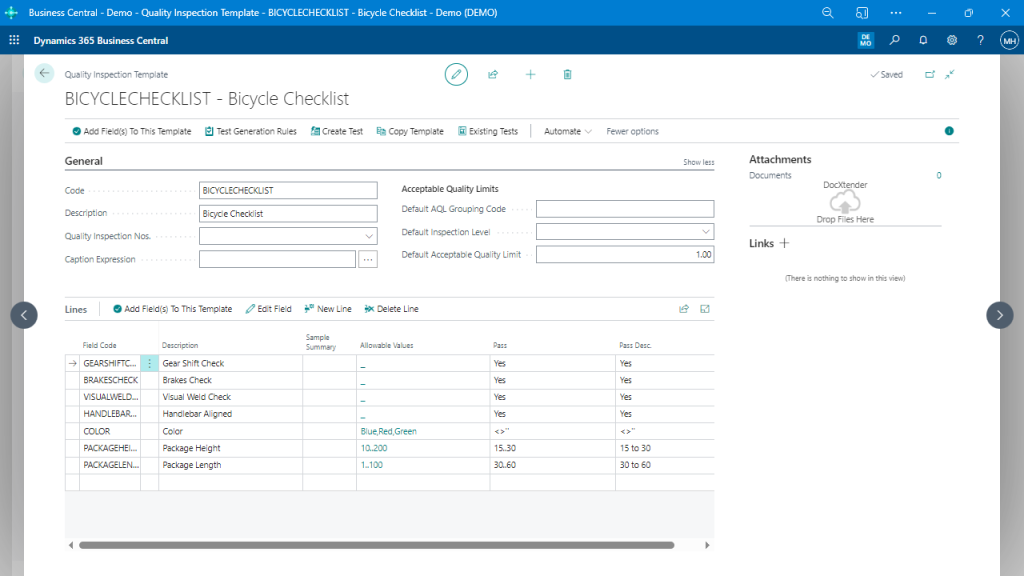

1. Improve Your Test Templates

If one test field consistently fails—such as temperature, weight, or packaging—review the related template. You might need to adjust your test ranges or tighten your criteria.

This template allows users to create and manage detailed checks on various components, ensuring thorough quality assessments and high-quality production.

2. Keep an Eye on Supplier Quality

Sort your test results by vendor. If one supplier sends more failed items than the rest, use that information in your next meeting with them. Back up the conversation with data.

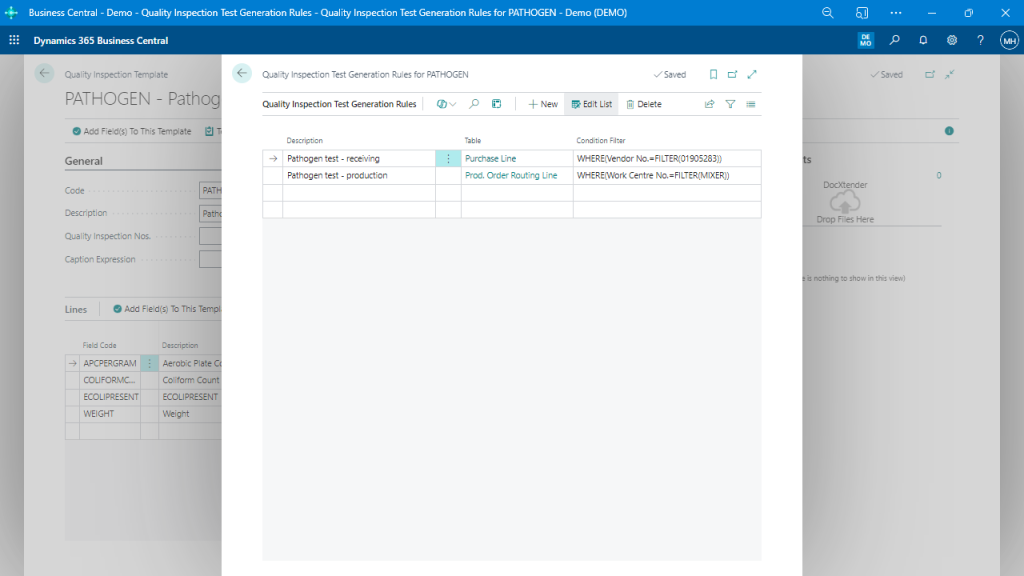

3. Add Extra Tests Where You Need Them

If one area of your operation—such as a specific work center—causes more failures, adjust your testing rules accordingly. Add inspections after high-risk steps or when specific conditions occur.

Set up and manage test generation rules for quality inspections in the production and receiving stages. Users can define specific conditions and tables for triggering tests, enhancing compliance and efficiency.

4. Use Grades to Control What Happens Next

Grades help you decide what to do after a test finishes. You might stop failed items from being sold, send them for retesting, or place them in a QA hold bin until someone checks them out.

Automate Your Response

When a test fails, you shouldn’t have to follow up manually every time. Utilize the Quality Inspector’s workflow tools to automate the next steps.

You might send an alert, put the item on hold, or create a task for the QA team to address.

Keep Things Moving with Mobile Inspections

Your inspectors don’t always sit at a desk. Sometimes they’re on the floor, in the warehouse, or at the receiving area. That’s why mobile testing matters.

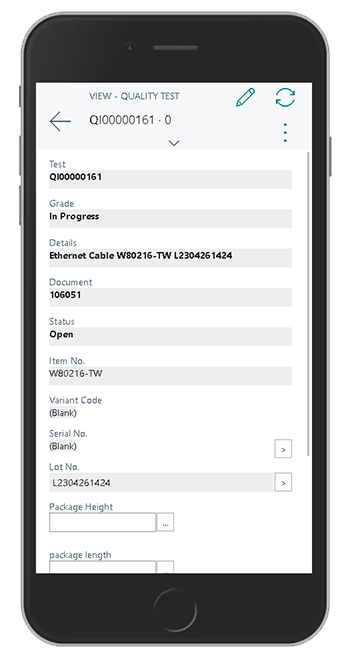

Use the Quality Test on Phone feature to capture results directly from a mobile device—no delays and no paperwork.

Conduct quality tests conveniently on your phone with the Quality Test on Phone feature in the Quality Inspector app by Insight Works, optimized for Business Central mobile clients.

Use Your Data to Drive Real Change

You already collect the right data. Now it’s time to use it to improve your process. Here’s how to get started:

- Filter your inspection data in Business Central.

- Export it to Excel or pull it into Power BI.

- Look for trends in failures, fields, vendors, or work centers.

- Update your templates and test rules to address what you find.

- Set up workflows so the system reacts when something goes wrong.

Better quality starts with better decisions—and those decisions come from using the data you already have.

To learn more about the Quality Inspector app, visit https://QualityForDynamics.com or reach out to your Microsoft Partner today.