Stop BOM Bloat: How to Handle Configure-to-Order in Business Central

Business Central’s standard Bill of Materials is brilliant when you build the same product day in and day out. The moment a customer starts mixing colors, swapping motors, or asking for an extra drawer, that simplicity bites back. Suddenly, the team is cloning items, pasting routings, and juggling spreadsheets to keep engineering and planning in sync—all while sales wait for a quote.

Why the Native BOM Runs Out of Steam

In the base application, every variant—purple frame, blue frame, maple top, oak top—must exist as its own item or as a long variant list. That forces three headaches. First, the item ledger explodes with near-duplicates that differ only by paint or length. Second, engineering time balloons because each tweak needs a copy-and-paste BOM and routing. Third, planning loses visibility whenever sales take shortcuts with free-text lines to speed things up. Throw in option-dependent rules (“if the bench is eight feet long, add two extra supports”), and the model simply can’t describe reality.

Adding a Configuration Layer—Inside BC

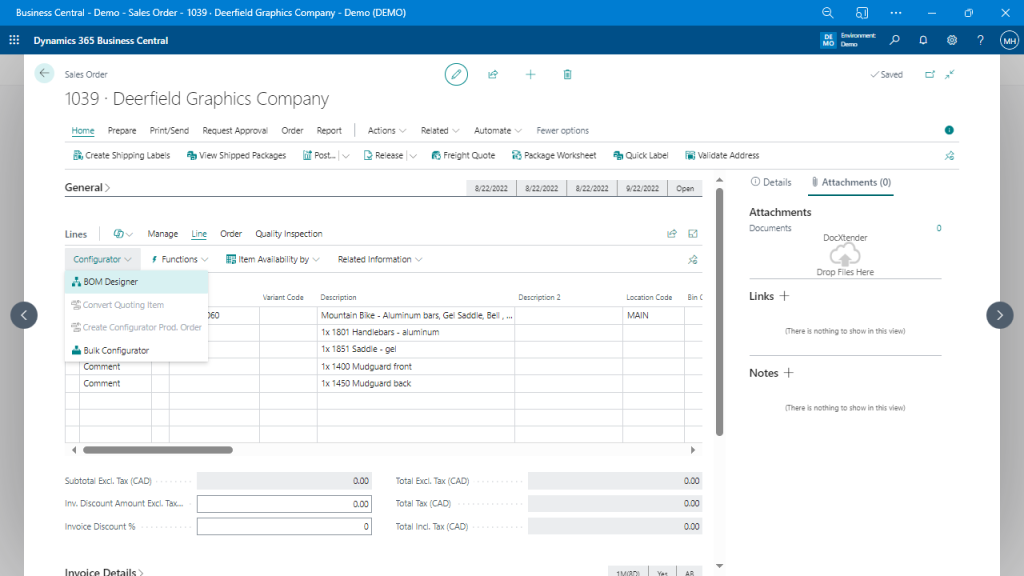

The fix is not another external CPQ portal; it’s a configuration layer that lives right in Business Central. On a sales-order line, a user clicks “Configurator” and launches BOM Designer. They remain on their familiar BC page, so permissions, dimensions, and posting groups stay intact.

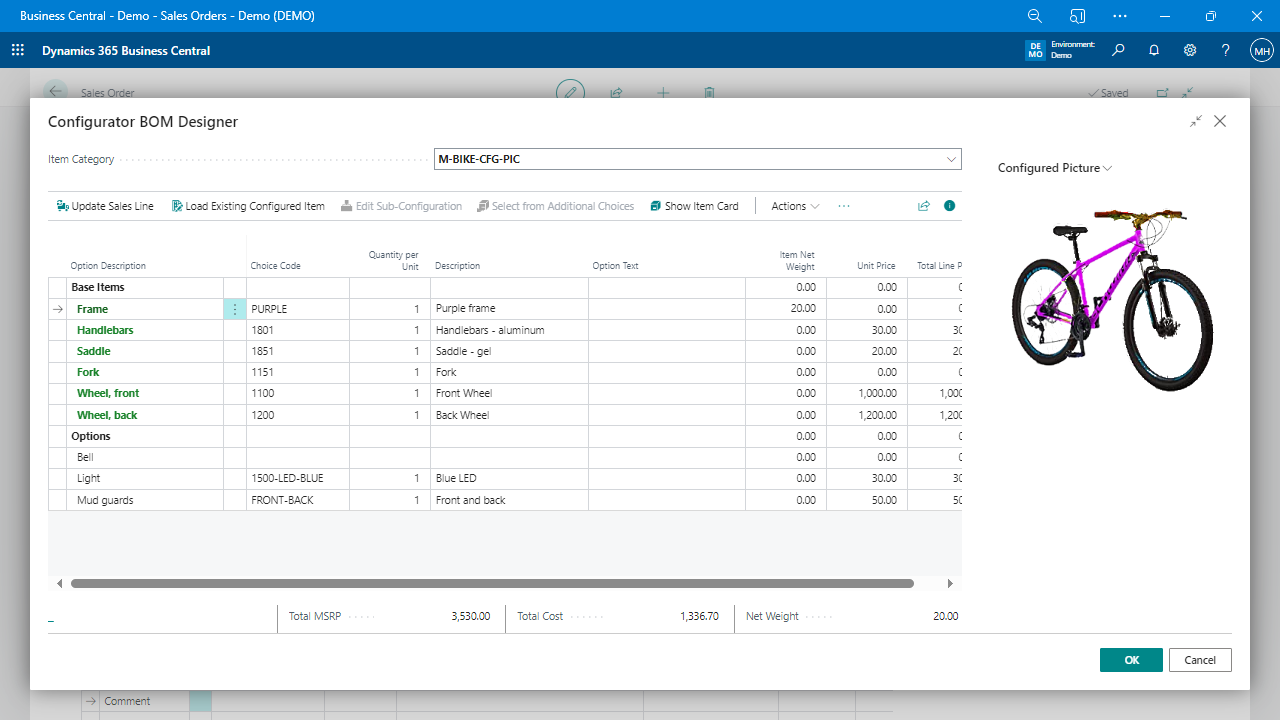

Inside BOM Designer, the product is broken into logical options: frame, handlebars, finish, and accessories. As choices are made, the page updates cost and weight and even shows a rendered picture. Behind the scenes, a rule engine enforces logic: choose aluminum handlebars, and the system can suggest a matching light; pick an oversized top, and it inserts extra brackets automatically. When the user presses OK, the configurator generates a clean Assembly or Production BOM plus a routing, assigns a smart item number (or re-uses a generic quoting item), and drops the result back onto the sales line—instantly priced and ready for MRP.

Configurator menu on a sales-order line – launch all configuration actions without leaving the standard Business Central page.

BOM Designer in action – choose options, apply rules, and watch cost and weight update instantly before committing the build.

A Day in the Plant

Picture the custom-furniture team. A client asks for a maple workbench, eight feet long, powder-coated black, with three drawers and a cable grommet. Sales opens the order, fires the configurator, and follows a guided conversation:

- Size: selects eight feet; edge-band footage recalculates automatically.

- Top material: picks maple; finish options filter to those compatible with hardwood.

- Drawers: enters “3”; a rule adds heavy-duty slides and extends assembly time by ten percent.

No one calls engineering, and no one edits Excel. The newly generated BOM flows to planning; purchasing sees the extra slides; the shop floor prints bar-coded pick tickets—turnaround time: two minutes. The same flow can handle a bicycle, a valve assembly, or a configured pump—anything that follows option-and-rule thinking.

Implementation Pointers

Start with one high-volume, high-variability product family. Catalog its options and rules on paper before entering them. Re-use BC data templates so every created item inherits posting groups and replenishment methods. Train sales to quote the configurable item instead of creating ad-hoc stock codes. Finally, review costing: because the configurator rolls standard costs on the fly, margin analysis stays accurate even when the product has never been built before.

So What’s Driving the Magic?

Everything described in this article comes from Product Configurator by Insight Works — https://CPQforDynamics.com. The extension overlays option logic, rule-based BOM/routing generation, and smart item numbering on standard Business Central—no external database, no duplicate master data.

Takeaway

Static BOMs fit repeat manufacturing; configurable products need dynamic structures. Embed a configurator in Business Central, and the operation will quote faster, eliminate spreadsheet gymnastics, and give planning perfect visibility—all without leaving the system already in place.