Why Warehouse Mobility Breaks Down in Business Central

Listen to the Podcast

Real-Time Scanning Replaced by Delayed Paper Processes

Warehouse staff often rely on paper forms or manual notes to record receiving, put-away, and picking activities. These records get entered into the system at a later time, causing discrepancies between actual inventory and what Business Central shows. Operators frequently find that stock counts don’t match system quantities due to missed or late data entry.

In addition, manual transaction recording can lead to errors or missing information, which accumulates and complicates inventory reconciliation. Workers note delays and confusion because the system reflects outdated inventory statuses, making timely decision-making difficult on the warehouse floor.

Inventory Updates Are Batch Processed Physical Movement Occurs Without Immediate System Posting

The core issue arises because physical inventory movements occur continuously, but system updates happen in batches or after delays, separating actual work from recorded transactions. Without immediate posting, available inventory numbers lag behind reality, leading to operational uncertainty.

Furthermore, many warehouse processes depend on user memory or manual input, which is error-prone and inconsistent. The lack of enforced scanning at key transaction points allows discrepancies to build up before they are detected and corrected.

Real-Time Scan Driven Transaction Posting

To prevent inventory discrepancies, each warehouse action must be captured at the point of work using barcode scanning or similar technologies. Transactions should post immediately, ensuring Business Central reflects current stock levels and locations.

Additionally, controls need to validate scanned data against expected movements, confirming accuracy and preventing unauthorized or incorrect postings. These capabilities require seamless, handheld data capture integrated directly with warehouse processes.

How Business Central Handles Warehouse Transactions

Microsoft Dynamics 365 Business Central provides inventory and warehouse functionality that supports bin-level tracking, item ledger entries, and basic put-away and picking processes. Transactions can be posted through various journal and worksheet pages, but native workflows often rely on manual batch posting rather than real-time updates.

While Business Central tracks inventory movements and statuses, it assumes timely and accurate data entry. It does not enforce barcode scanning or immediate transaction posting out of the box, which creates gaps between physical activity and system records.

When Native Posting and Validation Aren’t Enough

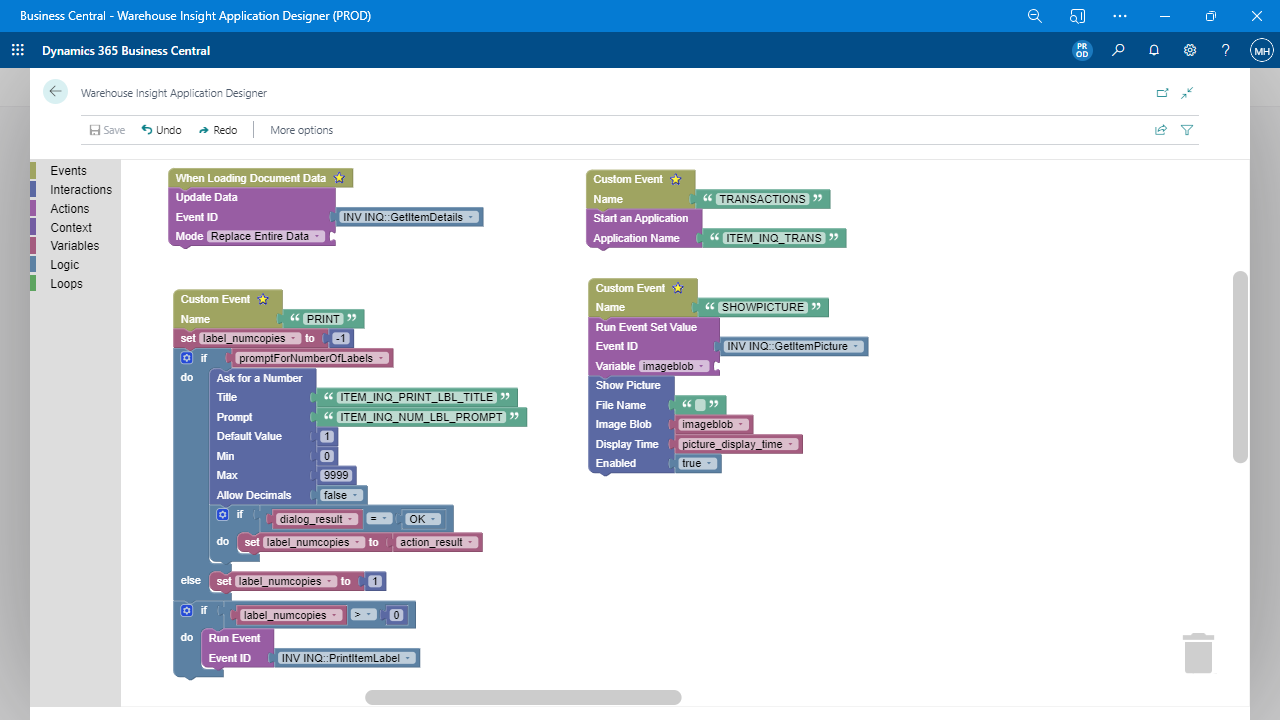

Standard Business Central workflows lack enforced, real-time warehouse execution controls, which leads to delays and errors in inventory data. Insight Works offers Warehouse Insight, a warehouse execution system that integrates mobile barcode scanning and transaction validation directly with Business Central. This app captures receiving, put-away, picking, and movements at the point of work and posts transactions immediately to the system, reducing data lag and errors.

For facilities that manage mixed items or containers, the License Plating extension adds efficiency by enabling single-scan operations for groups of items. Additionally, the Barcode Generator PowerTool enhances label printing and barcode generation to support customized scanning workflows. Together, these Insight Works apps extend Business Central’s capabilities to deliver accurate, real-time warehouse execution.

Real-Time Control Requires Process Integration

Warehouse inventory accuracy depends on capturing and posting transactions as work happens, not after delays. This is a structural challenge that requires enforcing scan-driven controls integrated within operational workflows. Clear data and immediate updates are fundamental to reliable warehouse management.