Dynamics 365 Supply Chain Management: Understanding master planning margins

The safety margin or safety time feature of Dynamics 365 Supply Chain Management changes master planning dates. This can be confusing! So this is a feature that has to be used with care. The Master planning user, trying to understand what the Net requirement screen is showing, can easily get confused because the dates are not immediately understandable anymore when using margins.

The legitimate business purpose for this feature is to provide a time buffer that the business process needs for some reason. A classic example that I have seen used in actual implementations is the inspection time for incoming purchased material. We don’t want to put extra days in the supplier lead time, which would defeat the purpose (the supplier would “use” our buffer), but we need an internal buffer for this inspection time. We wish that the PO would arrive somewhat earlier then the date it is actually needed.

There are three types of safety margins, and it is very strongly recommended to only use one of them at a time because they “build on each other”, obviously.

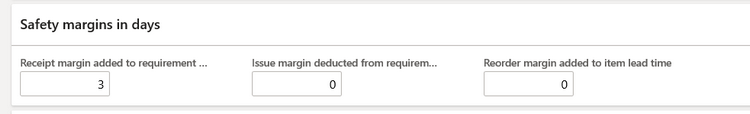

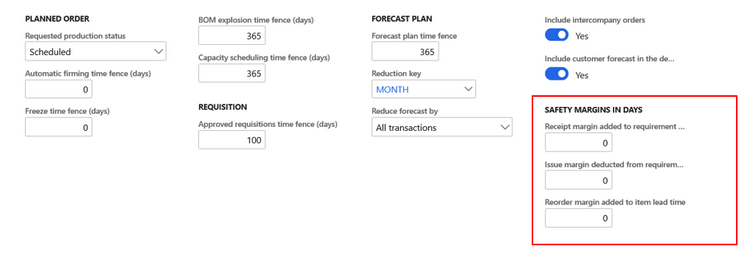

The three fields exist on the Master Plan:

And the same fields are on the Coverage Group:

The values on coverage group and master plan are cumulative. I found this very strange and surprising and in all those years I have never found a real-life situation where you would want this. We are used to having the same fields on the Coverage group ...

FREE Membership Required to View Full Content:

Joining MSDynamicsWorld.com gives you free, unlimited access to news, analysis, white papers, case studies, product brochures, and more. You can also receive periodic email newsletters with the latest relevant articles and content updates.

Learn more about us here