Finite Capacity Scheduling in Business Central: Why It Matters for Manufacturers and How MxAPS Delivers

Manufacturers using Microsoft Dynamics 365 Business Central often face a familiar challenge: schedules that look great on screen rarely hold up on the shop floor. Machines overlap, workers wait, and deadlines slip.

The MxAPS app from Insight Works, seamlessly integrated with Business Central, drives manufacturing excellence with advanced finite capacity scheduling in Business Central. The app helps manufacturers replace guesswork with accurate, executable plans.

MxAPS generates optimized production schedules that reflect actual capacity, available labor, and material readiness.

Why Finite Capacity Scheduling Matters

Traditional scheduling in Business Central assumes an unlimited resource allocation. The system backward-schedules production from due dates without checking if machines or workers are available. This approach leads to bottlenecks, overtime, and unrealistic start dates.

Finite capacity scheduling changes that. Schedules align with real-world limits, ensuring that every machine, person, and process remains productive without overloading.

Manufacturers gain:

- Better visibility into resource availability.

- Shorter and more predictable lead times.

- Reliable delivery performance with fewer last-minute changes.

Smarter Scheduling with MxAPS

MxAPS transforms production scheduling into an automated, data-driven process. Instead of manually dragging and dropping jobs, planners automatically generate a realistic schedule in seconds. The system evaluates every machine, work center, and shift before creating an optimized plan that meets delivery goals.

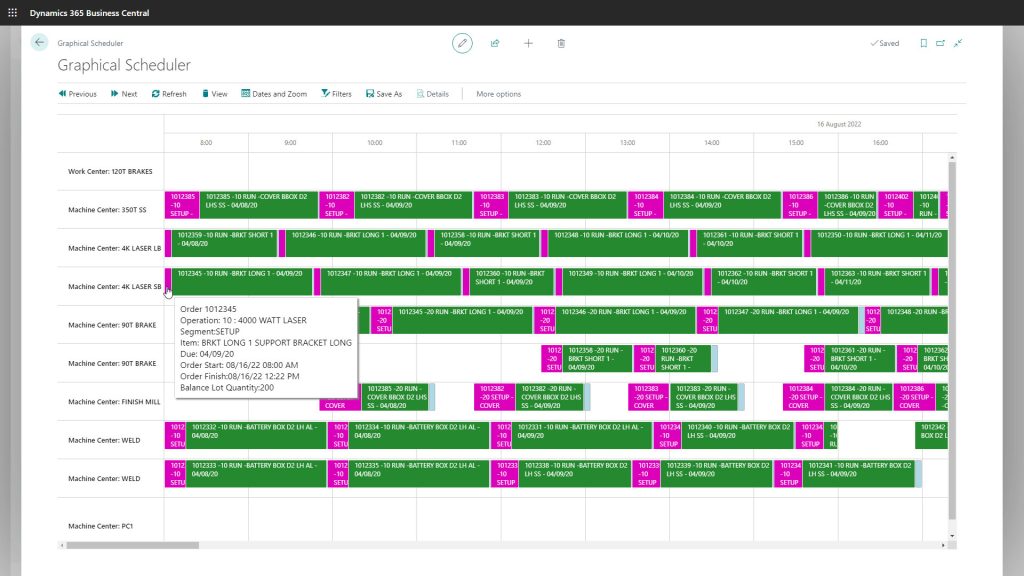

Schedulers focus on improving efficiency instead of managing conflicts. MxAPS balances workloads, sequences similar jobs to reduce setup time, and prevents overlapping operations that cause downtime.

MxAPS’s Scheduler: Simplify complex data, visualize schedules, and achieve production goals faster with an intuitive view of operations.

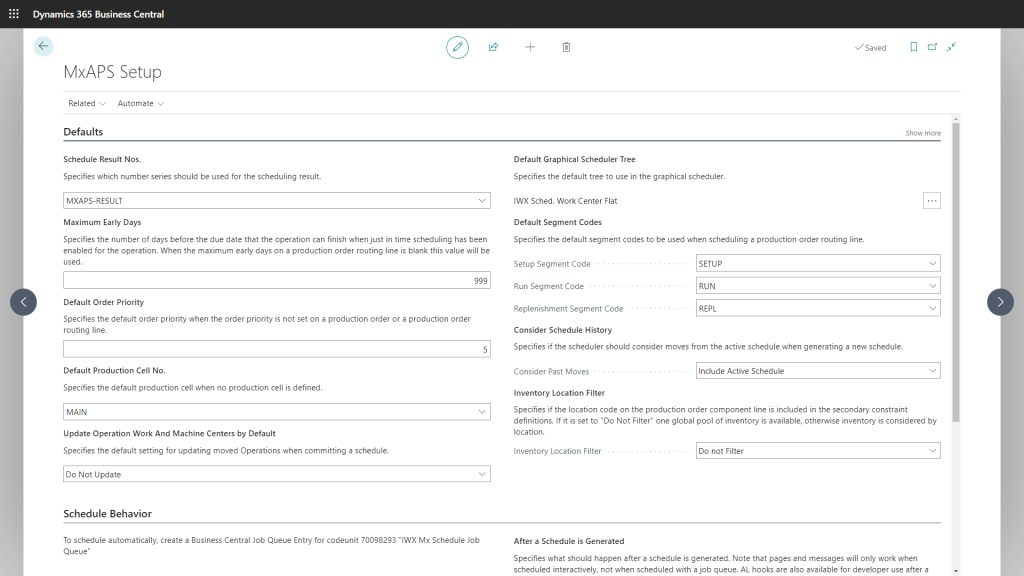

Simple Setup, Powerful Configuration

MxAPS includes a guided Setup Wizard that walks users through the configuration process. Planners choose a base setup, import demo data, or start directly with their own production environment.

MxAPS Setup: Optimize production schedules with MxAPS Setup. A user-friendly interface simplifies initial configuration for tailored system customization.

Once installed, teams define production cells, set scheduling rules, and establish priorities that align with real-world operations. The interface remains approachable, making complex scheduling accessible to everyone.

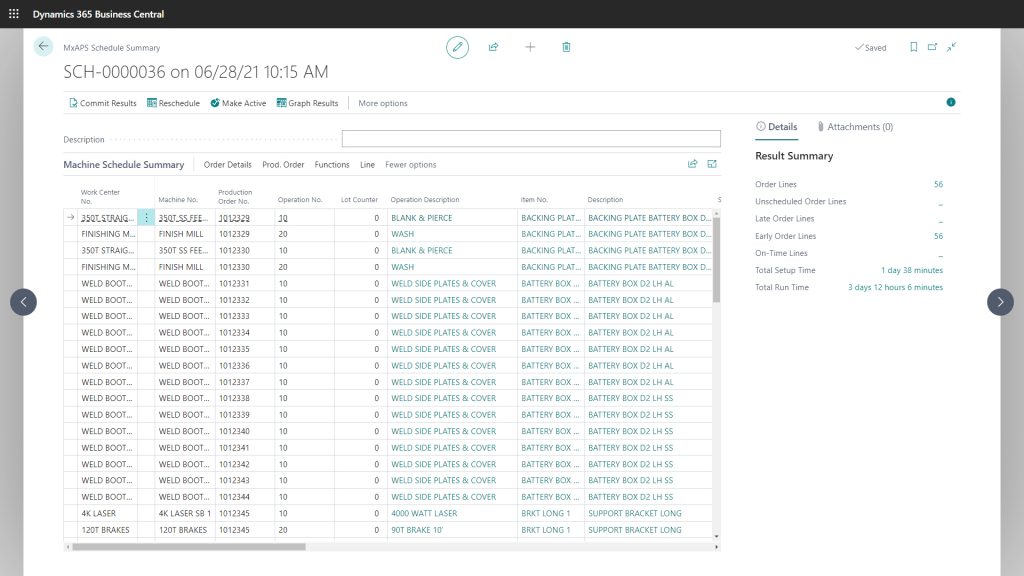

Clear Visibility into Every Schedule

MxAPS provides transparency that helps planners make confident decisions. The Schedule Summary page displays early, on-time, and late orders, setup hours, and total run time.

Schedule Summary: Use Schedule Summary in MxAPS for a complete production overview. Evaluate efficiency, order status, and resource use at a glance. Stay on track and make informed decisions effortlessly.

Planners use MxAPS to:

- Evaluate performance and identify bottlenecks.

- Adjust schedules quickly when capacity or priorities change.

- Compare different scenarios to see how each impacts delivery timelines.

Rules That Match Real Operations

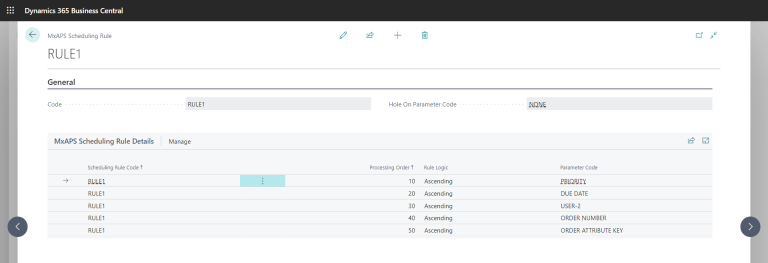

Every manufacturer runs differently, and MxAPS respects that. Configurable scheduling rules define how production orders are prioritized and sequenced, so schedules reflect each company’s unique workflow.

Scheduling Rule: Maximize flexibility and control with MxAPS. Customize scheduling rules to fit your needs, streamline processes, and boost efficiency. Stay ahead with smart scheduling.

Manufacturers create rules that:

- Sort jobs by due date, material type, or setup sequence.

- Group similar materials to minimize changeovers.

- Prioritize rush orders without disrupting the overall plan.

Reliable Schedules, Confident Delivery

Manufacturers using MxAPS gain practical control over production. The app eliminates double bookings, prevents overloads, and creates schedules that accurately reflect real capacity. Planners gain a clear view of what they will produce and when, reducing downtime and improving delivery accuracy.

Finite capacity scheduling transforms production planning into a confident and repeatable process. With MxAPS and Business Central working together, manufacturers move from reacting to predicting—and from delays to dependable results.

Visit SchedulingForDynamics.com to learn more about how MxAPS helps manufacturers achieve greater control, efficiency, and confidence in their production planning, or contact your Microsoft Partner today.