How Manufacturers Automate Preventive Maintenance with Business Central

In manufacturing, downtime drains productivity, inflates costs, and throws production schedules off balance. Without a structured maintenance system, even minor issues snowball into major disruptions. With the Maintenance Manager app from Insight Works, manufacturers using Microsoft Dynamics 365 Business Central take complete control of preventive maintenance.

The app uses real-world data—such as runtime, output counts, or calendar-based intervals—to automatically generate work orders before problems occur.

Maintenance Manager streamlines maintenance, maximizes uptime, and ensures assets last longer. By replacing manual processes with automation, maintenance teams eliminate guesswork and stay ahead of costly breakdowns.

Here’s how to set it all up and make it work—right from inside Business Central.

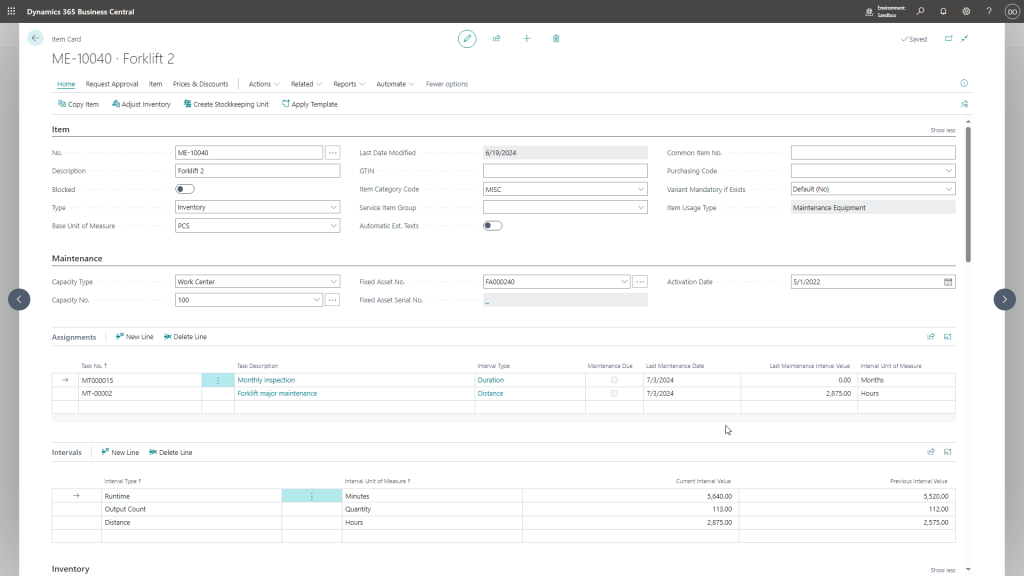

Step 1: Track Equipment the Right Way

Before assigning maintenance tasks, define the equipment you want to monitor. Think of machines, vehicles, tools, or any production asset.

Head to Maintenance Equipment Assets in Business Central. From there:

- Link existing Fixed Assets or create standalone maintenance items.

- Set the activation date to reflect the equipment’s first use.

- Specify whether to manage inventory (track as zero-cost stock) or treat equipment as non-inventory.

Once defined, the system starts tracking usage through runtime, output, or time-based data—depending on your configuration.

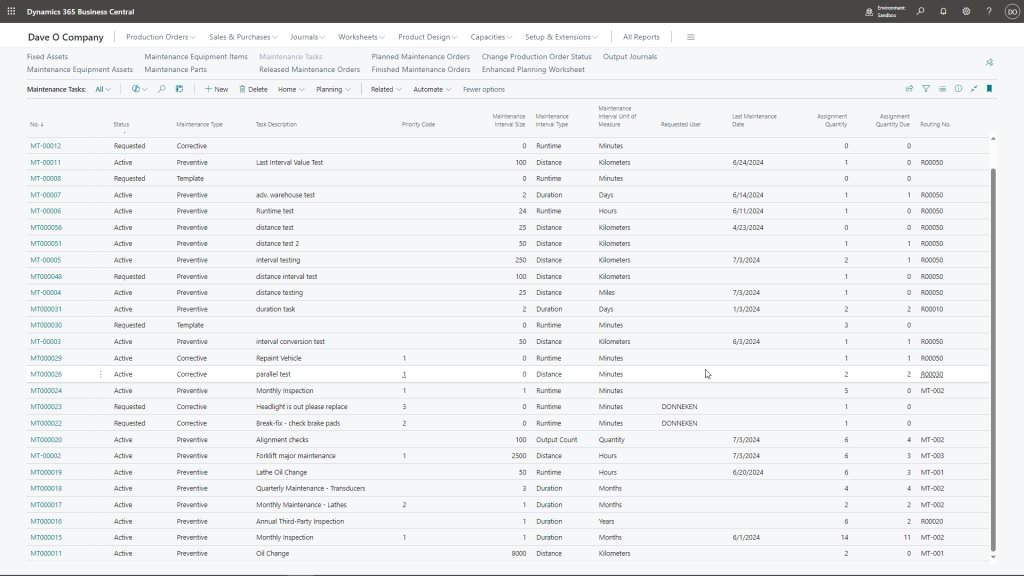

Step 2: Define Tasks and Set Maintenance Intervals

Next, create the actual maintenance actions. Whether it’s a belt inspection, filter replacement, or full calibration, each task gets tied to specific equipment.

- Navigate to Maintenance Tasks

- Select New

- Choose the maintenance type:

- Corrective – for break/fix issues

- Preventive – for scheduled intervals

- Template – for reusable task formats

From here, assign the task to one or multiple equipment records. Then define one or more intervals to trigger work orders:

- Runtime-based: e.g., every 500 hours

- Output-based: e.g., every 10,000 units produced

- Duration-based: e.g., every 30 days

The system tracks runtime and output automatically through posted production orders, so maintenance triggers stay aligned with real machine usage.

Step 3: Automate Work Order Scheduling

After you configure equipment and tasks, shift into automation. Maintenance Manager eliminates manual tracking.

- Open the Planning Worksheet

- Click Auto Schedule Tasks

- Enter a start and end date to define your planning window

- Confirm and generate the necessary work orders

This approach eliminates guesswork. Whether you’re scheduling for the current week or the next quarter, Business Central uses actual equipment usage data to schedule every task precisely when needed.

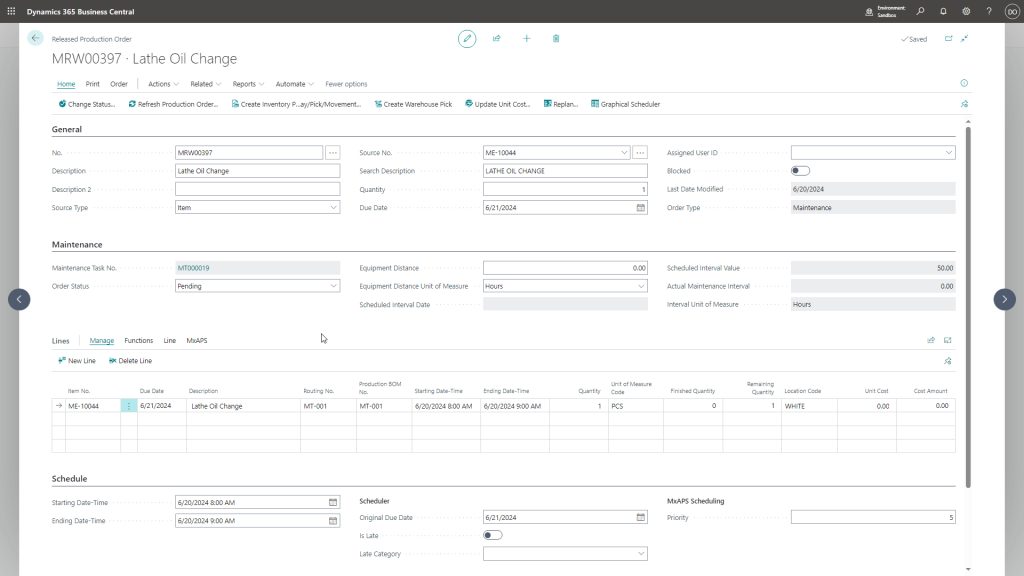

Step 4: Execute Maintenance Like Production

Once scheduled, maintenance orders function just like production orders in Business Central.

- Routing steps with labor time estimates

- Bills of materials for required spare parts

- Capacity reservations that block the asset during maintenance

- Work instructions for technicians

During execution, technicians:

- Record labor time

- Track parts usage

- Enter meter readings (e.g., updated runtime or mileage)

- Mark the task as complete

Once finished, the system updates the equipment’s intervals automatically and logs all activity in the asset’s history.

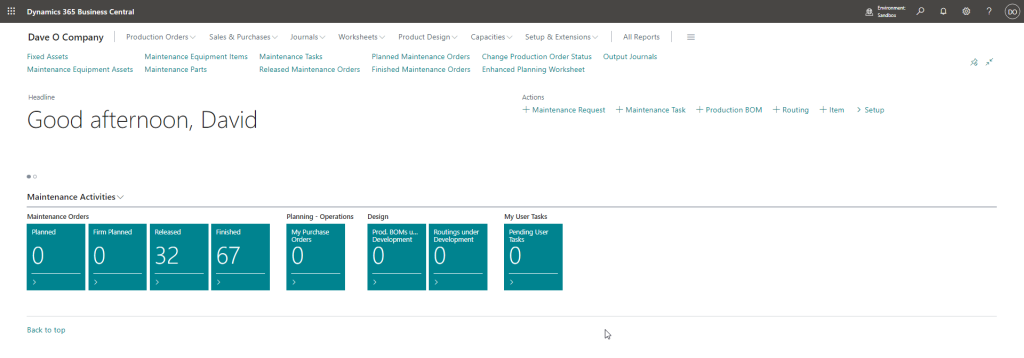

Step 5: Use Real-Time Views and Mobile Access

Visibility drives better decisions. Maintenance Manager offers several tools to keep managers and technicians in sync.

Use the Maintenance Calendar

View all scheduled tasks on a drag-and-drop calendar. Adjust timing based on technician availability or production needs.

Access Tasks on the Go

Technicians using the Business Central mobile app access:

- Job cards with detailed instructions

- Attached manuals and schematics

- Parts lists for each task

- Fields to record time and update interval values

Step 6: Keep Planning and Inventory in Sync

Maintenance Manager plugs directly into your inventory and planning workflows.

When maintenance tasks require spare parts, Business Central treats them like any other demand. Run your Planning Worksheet, and the system generates purchase suggestions for maintenance-related components.

As a result, the Planning Worksheet keeps your stock aligned with your maintenance plan—and avoids last-minute scrambles for parts.

Conclusion

Preventive maintenance no longer belongs on spreadsheets or whiteboards. With the Maintenance Manager app from Insight Works, manufacturers using Business Central eliminate surprises, protect critical equipment, and optimize labor and inventory.

By automating work order creation based on runtime, output, or scheduled intervals, maintenance becomes part of the production rhythm—not an interruption to it.

Ready to automate your maintenance? Explore more at MaintenanceForDynamics.com or talk to your Microsoft Partner to get started today.