Managing Maintenance Work Orders in Business Central: Best Practices for Success

Whether you’re in manufacturing, distribution, or facilities management, maintenance can make or break your operational uptime. That’s where a well-integrated Computerized Maintenance Management System (CMMS) comes into play. For organizations using Microsoft Dynamics 365 Business Central, the Maintenance Manager app from Insight Works provides a seamless way to generate, assign, and track maintenance work orders without leaving your ERP.

In this article, we’ll cover best practices for managing maintenance work orders in Business Central using Maintenance Manager—focusing on not just the how, but also the why behind each step. We’ll also highlight key screens so you can visualize the process in action.

Listen to the Podcast: Take Control of Equipment Downtime with Maintenance Manager in Business Central

Why Use Maintenance Work Orders in Business Central?

Before we jump into screens and workflows, here’s the business case:

- Extend equipment life with structured preventative maintenance

- Minimize costly unplanned downtime by tracking recurring tasks

- Ensure technician accountability with documented assignments and due dates

- Integrate seamlessly with inventory, production, and planning functions in Business Central

Maintenance Manager turns Business Central into a powerful CMMS by linking asset data, work centers, and inventory directly to your maintenance activities.

Getting Started with Maintenance Manager

Before you dive into maintenance tasks and work orders, you’ll need the app. You can start a free trial of Maintenance Manager directly from Microsoft AppSource:

- Visit AppSource

- Search for “Maintenance Manager by Insight Works”

- Choose your environment and install with one click

Once installed, launch the Setup Wizard from the Maintenance Manager menu in Business Central. This will pre-fill configuration data (like number series and templates), making the onboarding process painless—even if you’re not a CMMS expert.

Best Practice: Let the Setup Wizard do the heavy lifting before making any manual config changes. It creates a solid foundation for task and order management.

Step 1: Create a Maintenance Task

Every good work order starts with a task. In Business Central, maintenance tasks can be:

- Corrective (one-off repairs)

- Preventive (recurring based on time, output, runtime, or distance)

- Template-based (used for standardization)

You define details like frequency, routing, BOM, and assign equipment.

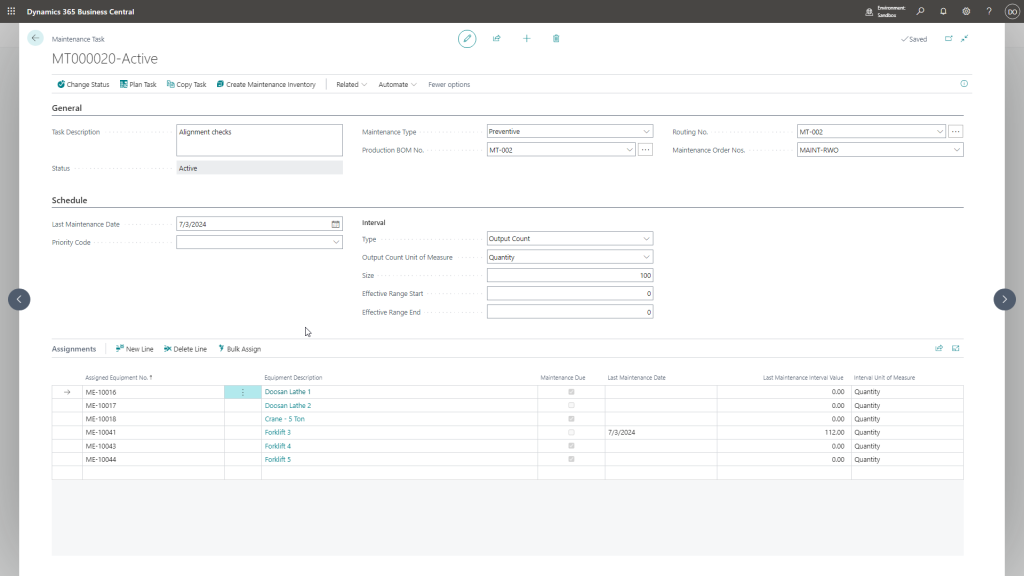

Here, we’re scheduling Alignment checks based on every 100 output units. Multiple pieces of equipment—like lathes and forklifts—are bulk-assigned.

Use the Maintenance Task card to define what’s being done, how often, and to which assets.

Step 2: Auto-Generate Work Orders with the Planning Worksheet

Rather than creating orders manually, Maintenance Manager leverages the Planning Worksheet in Business Central. Think of this as your maintenance scheduling hub.

You can generate orders based on:

- Due tasks (intervals met)

- Specific time windows (e.g., plan all June maintenance)

- Bulk creation for duration-based tasks (e.g., monthly inspections)

Once calculated, the Planning Worksheet proposes work orders that you can release or adjust.

Best Practice: Batch-generate orders for preventive maintenance monthly, so your technicians know what’s coming down the pipeline.

Step 3: Assign and Track Maintenance Orders

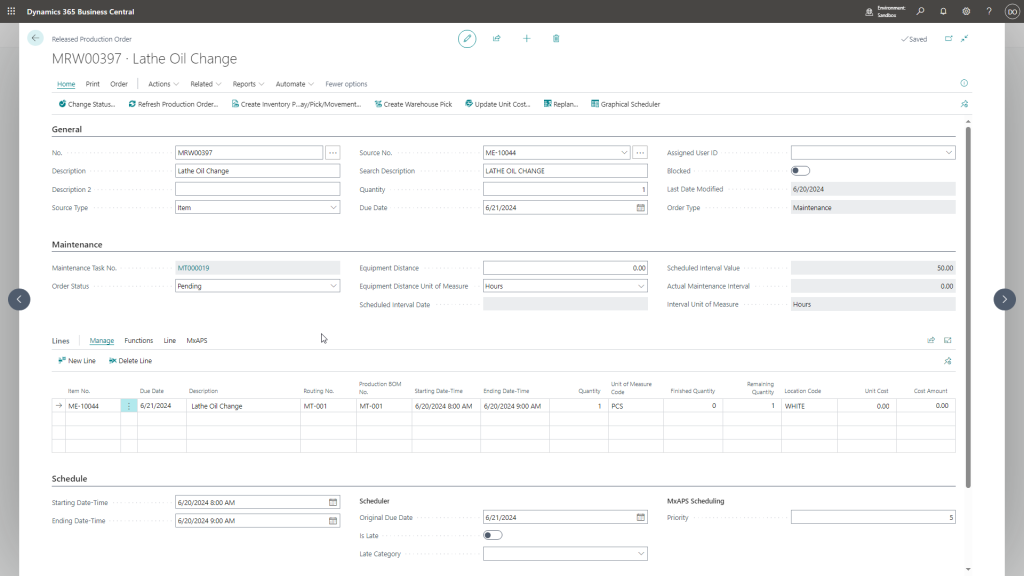

Once released, each Maintenance Order functions much like a production order—but tailored for maintenance. It includes:

- Task and equipment references

- Actual and scheduled maintenance intervals

- Time-stamped execution tracking

- Item consumption and routing

This structure provides full traceability, ensuring that maintenance work isn’t just scheduled—it’s done, logged, and auditable.

Released Maintenance Orders include detailed records of execution, from BOMs to work center time.

Step 4: Connect Equipment to Tasks and Intervals

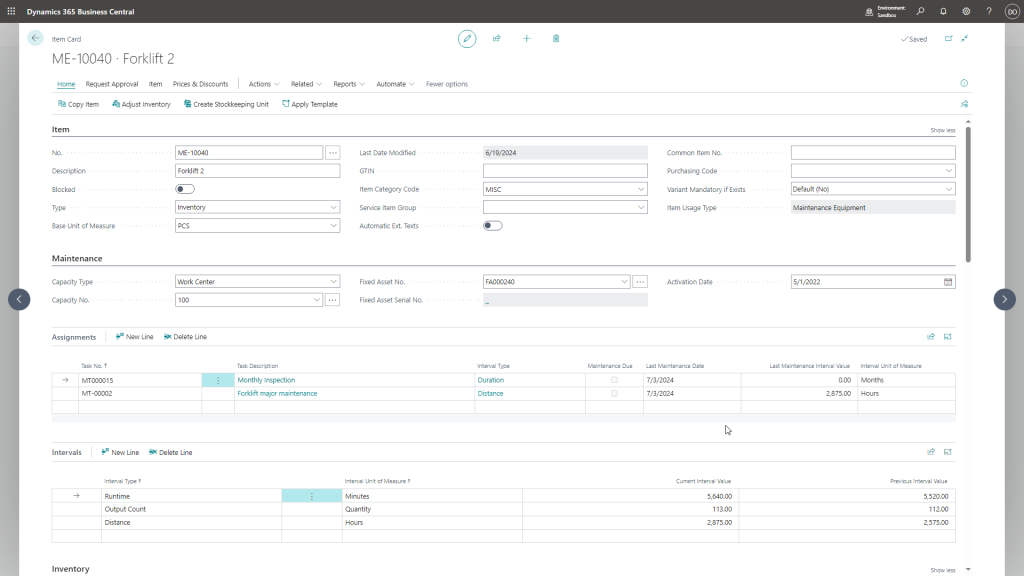

Each equipment item (like a forklift or CNC machine) can be linked directly to maintenance tasks and tracked across multiple intervals—runtime, output, distance, and duration.

By monitoring interval values, Business Central can automatically flag when a task becomes due, keeping your maintenance proactive instead of reactive.

See all maintenance tasks assigned to an asset and view the current interval readings from production.

Step 5: Review and Optimize from the Dashboard

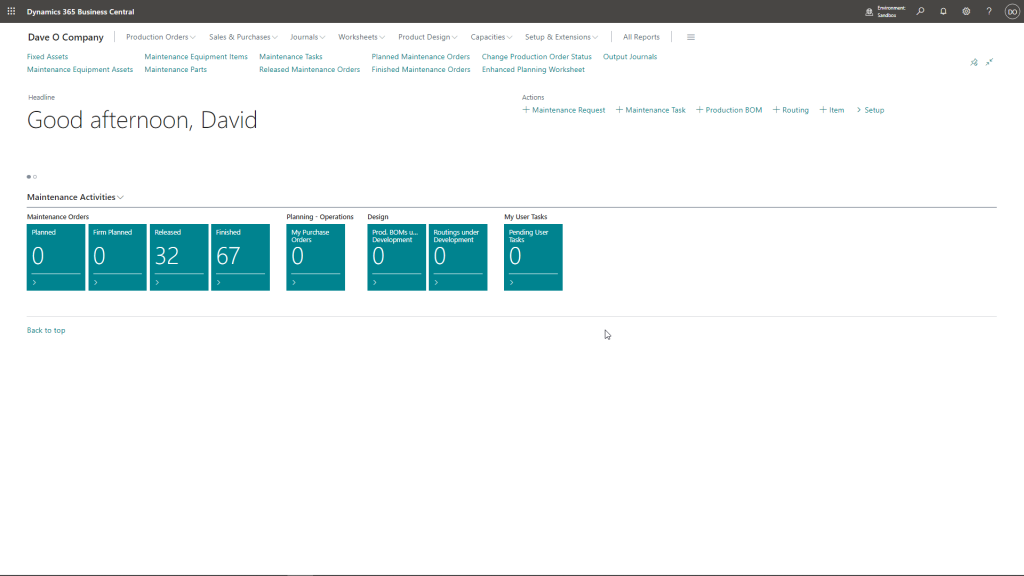

The Maintenance Manager Role Center gives an overview of all maintenance activities:

- Released and finished orders

- Pending tasks

- Work order trends over time

Use this dashboard to identify bottlenecks (e.g., too many pending orders) and adjust workload or task frequency accordingly.

The role center provides insight into your entire maintenance pipeline at a glance.

Benefits of an Integrated CMMS in Business Central

Let’s connect the dots between the features and the benefits you’ll see:

| Feature | Benefit |

|---|---|

| Asset-task linking with intervals | Automatically flag upcoming maintenance to prevent failures |

| BOM and routing integration | Standardize maintenance procedures and allocate resources |

| Planning Worksheet for task scheduling | Eliminate manual entry, improve forecasting |

| Maintenance Order tracking | Ensure work is executed and documented |

| Role Center visibility | Improve communication between planning, maintenance, and operations |

Whether you’re maintaining a fleet of forklifts or an entire production line, keeping everything inside Business Central simplifies your operations and ensures data integrity across departments.

Final Thought

A maintenance plan is only as good as your ability to execute it. With Maintenance Manager acting as your CMMS within Business Central, you get the structure, traceability, and automation needed to manage maintenance work orders with confidence.

Want to reduce downtime, stretch asset life, and free your team from spreadsheet hell? Start with structured maintenance tasks, automate your planning, and track your work with Maintenance Manager.