Why Business Central’s Standard Scheduling Isn’t Enough for Complex Production Planning

Manufacturers using Microsoft Dynamics 365 Business Central know that production scheduling can quickly become complicated. The built-in tools handle basic scheduling, but when multiple work centers, machine constraints, and shifting priorities come into play, things get complex. Schedules often look good on-screen but fall apart on the shop floor.

The MxAPS app from Insight Works, seamlessly integrated with Business Central, drives manufacturing excellence with advanced finite capacity scheduling in Business Central, helping manufacturers create accurate, executable production plans that reflect real-world conditions. The app transforms scheduling from a time-consuming task into an intelligent, automated process that keeps production running smoothly.

Understanding the Challenge with Standard Scheduling

Business Central’s standard scheduling uses backward scheduling and assumes infinite capacity. The system works backward from a due date to suggest a start date, often setting production to begin in the past. Machines and work centers appear to have unlimited hours, leading to overloaded schedules that no team could realistically execute.

Production managers spend hours manually moving tasks, adjusting timelines, and rescheduling orders. These workarounds may temporarily solve one issue but often create new ones, especially when priorities shift or downtime occurs.

MxAPS’s Scheduler: Simplify complex data, visualize schedules, and achieve production goals faster with an intuitive view of operations.

Moving Toward Finite Capacity Scheduling

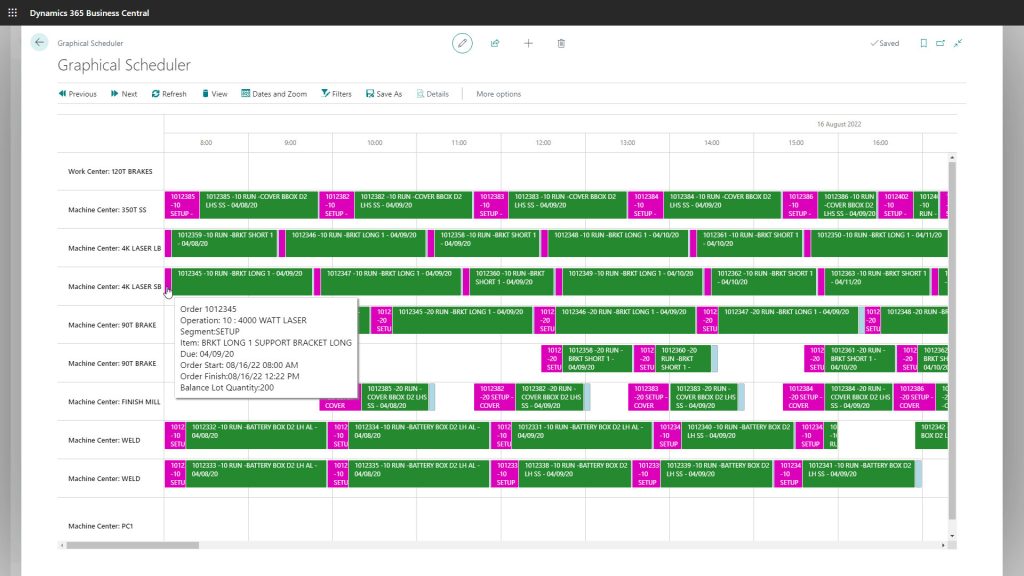

MxAPS replaces guesswork with precision. Using advanced algorithms, the app evaluates machine availability, labor, tooling, and materials before generating an optimized plan. Schedules become realistic, repeatable, and based on actual capacity rather than assumptions.

With MxAPS, production teams gain:

- Accurate schedules that align with available resources

- Smarter sequencing that minimizes changeovers

- Balanced workloads across machines and shifts

- Real-time visibility into order status

- Flexible what-if analysis to test new scenarios

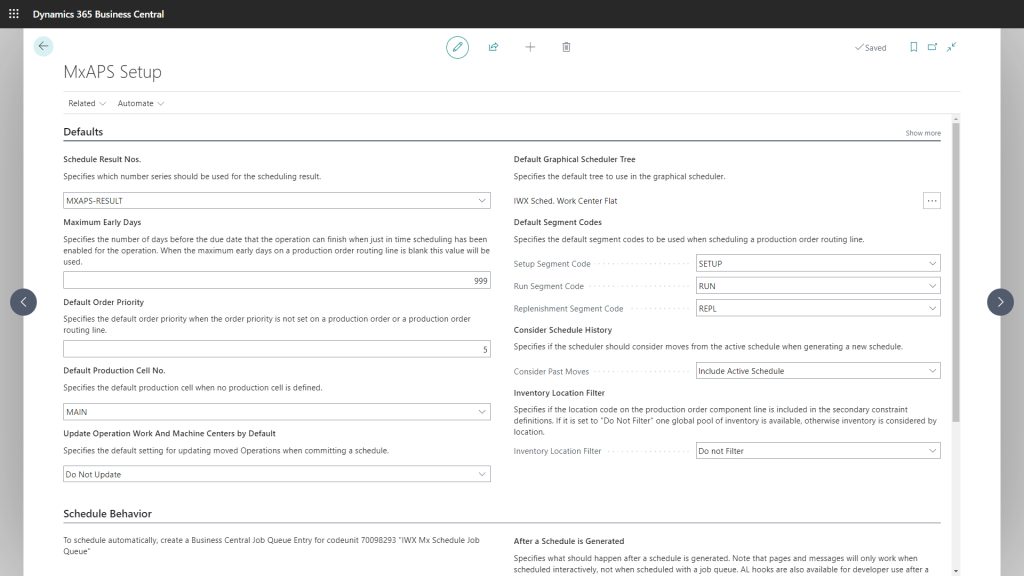

MxAPS Setup: Optimize production schedules with MxAPS Setup. A user-friendly interface simplifies initial configuration for tailored system customization.

Automating the Scheduling Process

MxAPS introduces a “hit a button and go” approach that automatically evaluates every possible scheduling option to create the most efficient plan. The system considers labor availability, material lead times, and setup durations to determine when and where each job should run.

Every plan reflects what can actually happen on the shop floor, allowing teams to focus on production rather than constant rescheduling.

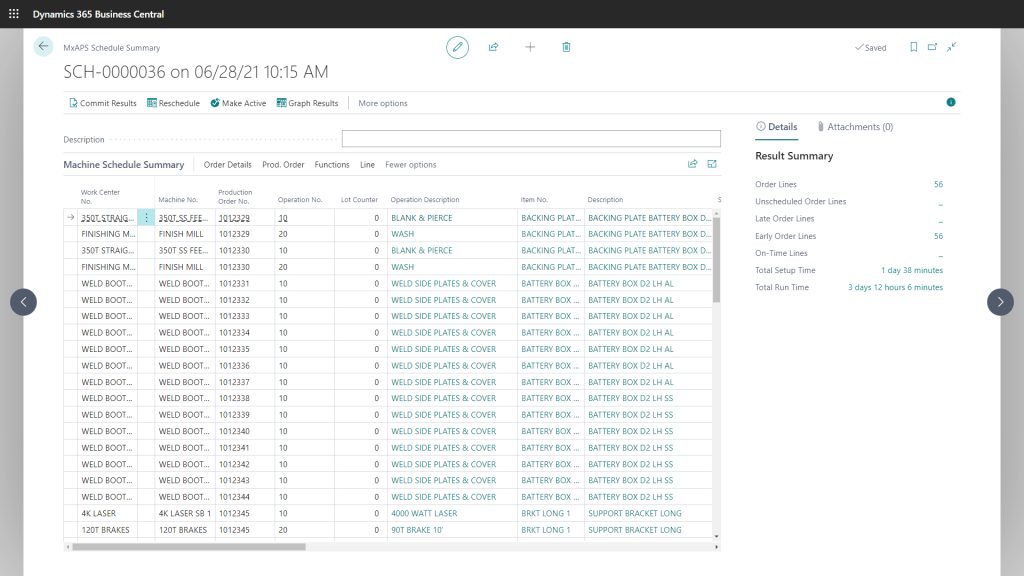

Schedule Summary: Use Schedule Summary in MxAPS for a complete production overview. Evaluate efficiency, order status, and resource use at a glance. Stay on track and make informed decisions effortlessly.

Real Benefits for Manufacturers

Manufacturers using MxAPS with Business Central see immediate improvements:

- Shorter lead times and smoother production flow

- Improved on-time delivery and customer satisfaction

- Reduced overtime and downtime costs

- Stronger confidence in planning decisions

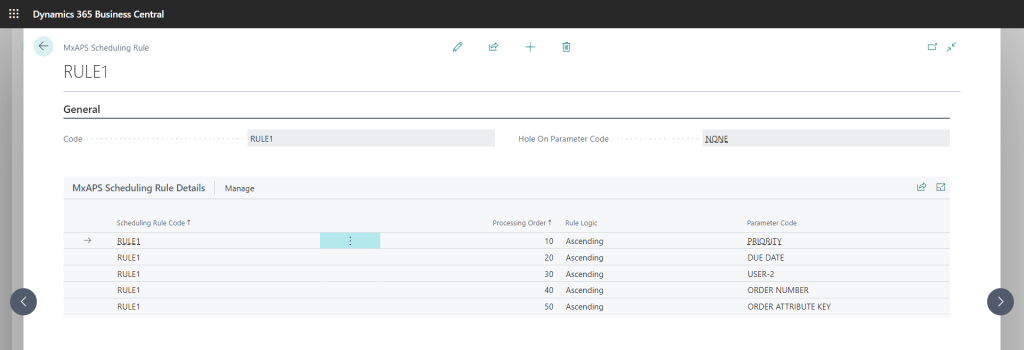

Scheduling Rule: Maximize flexibility and control with MxAPS. Customize scheduling rules to fit your needs, streamline processes, and boost efficiency. Stay ahead with smart scheduling.

Why MxAPS Complements Business Central

Business Central offers solid production management tools, but MxAPS extends those capabilities with automation, intelligence, and predictive insights. The app brings the power of finite capacity scheduling to complex environments, helping teams plan smarter and operate with greater accuracy.

When manufacturers move from manual adjustments to data-driven planning, production becomes more predictable and efficient. Teams know what to produce, when to produce it, and how to use resources effectively.

The Bottom Line

Standard scheduling in Business Central provides a foundation, but MxAPS delivers the whole picture. By combining advanced algorithms with seamless integration, MxAPS enables manufacturers to plan confidently, meet customer demands, and maintain control over complex production operations.

Visit SchedulingForDynamics.com to discover how MxAPS enhances accuracy and balances in your scheduling process or reach out to your Microsoft Partner today.