Azure IoT for manufacturers: Evaluating current capabilities and the future potential

FREE Membership Required to View Full Content:

Joining MSDynamicsWorld.com gives you free, unlimited access to news, analysis, white papers, case studies, product brochures, and more. You can also receive periodic email newsletters with the latest relevant articles and content updates.

Learn more about us here

In the past, machine operators and factory managers had no way of foreseeing when a machine would begin to perform poorly or completely shut down. If something went wrong, getting the equipment back up and running was often time-consuming, using trial-and-error troubleshooting.

And for manufacturers, any unexpected downtime meant slowed or ceased production, which resulted in reduced productivity and higher costs.

The latest generation of IoT solutions helps a broader range of manufacturers gather insights that allow them to predict outcomes and perform better data analysis while addressing industry-specific requirements. Manufacturers are investing more time and effort in finding feasible ways to improve efficiency and drive profitability based on the power of today’s IoT capabilities. Common goals include:

- Shifting from reactive to predictive business models to safeguard business via data-driven decisions and deliver top-quality service.

- Converting data into actionable insights by applying AI to IoT solutions to target specific manufacturing activities like intelligent scheduling.

- Utilizing real-time information on equipment performance and proactively maintaining it before an incident occurs.

- Incorporating high-end IoT-enabled next-gen machines equipped with sensors allows them to improve security, connectivity, performance, efficiency, and desired profitability.

- Monitoring intelligent IoT-enabled machines from remote locations, resulting in less time to market manufactured products.

Moving into intelligent manufacturing begins with enterprise-ready cloud computing services like Microsoft's Azure IoT solution. Services from the Azure IoT cloud power complex industrial operations at a global scale. Microsoft has already promoted some compelling IoT successes ranging from licorice extrusion (Hershey’s) to jet engine efficiency (Rolls-Royce) to reductions in production and operational downtime (thyssenkrup, TetraPak, Johnson Controls).

In today's highly competitive manufacturing market, there are three questions any business leader should look for when considering an investment in IoT today:

- Can the technology provide smooth service to customers?

- Can IoT reduce overall costs?

- Can the chosen technology solution lead to increased revenue?

IoT has the power to answer these questions and unlock great business impact. As per the current stats from Dataprot, 83% of manufacturers improved efficiency and productivity with IoT, whereas 58% of manufacturers find IoT strategically essential for digitally transforming industrial operations.

Current statistics also say that 90% of manufacturers now consider IoT as critical to the overall success of their business, while 80% of companies have increased revenue due to IoT implementation.

In this article we will explore:

- What is Azure IoT?

- Industry 4.0 use cases

- What is Microsoft IoT Plug and Play, and why is it interesting?

- Azure IoT Central’s use of Microsoft IoT Plug and Play

- Looking ahead: IoT and the future of innovation

What is Azure IoT?

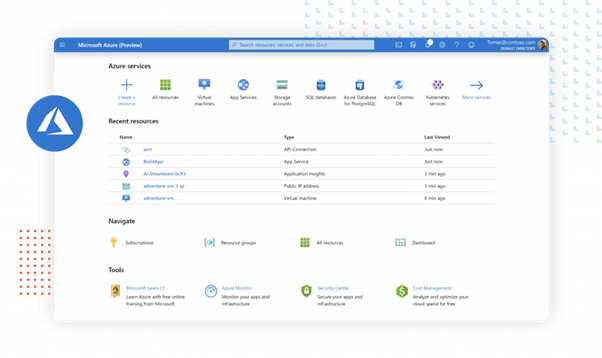

Azure IoT is a group of Microsoft-managed cloud services. Azure IoT is capable of connecting, monitoring, and controlling billions of IoT devices.

IoT devices are electronic circuit boards with embedded sensors and Unique Identifiers. They can use Wi-Fi and other wireless communications like cellular/4G/5G in needed situations like devices in the field to connect to the Internet to exchange information and data, e.g., a pressure sensor on a remote oil pump.

An IoT solution exists when one or more IoT devices begin communicating with one or more back-end services.

Some of the goals of manufacturers investing in Azure IoT include:

- Reducing the time to market products and services.

- Connecting, monitoring, and controlling all IoT-enabled products.

- Gain insight to make present and future-oriented business decisions.

- Accessing data anytime, anywhere, and on any device.

Industry 4.0 use cases

With IoT's help, manufacturers can accelerate their path to Industry 4.0 quite easily. McKinsey has outlined a broad range of potential use cases related to automation, digital management, analytics, digital experiences, and work methods.

FREE Membership Required to View Full Content:

Joining MSDynamicsWorld.com gives you free, unlimited access to news, analysis, white papers, case studies, product brochures, and more. You can also receive periodic email newsletters with the latest relevant articles and content updates.

Learn more about us here